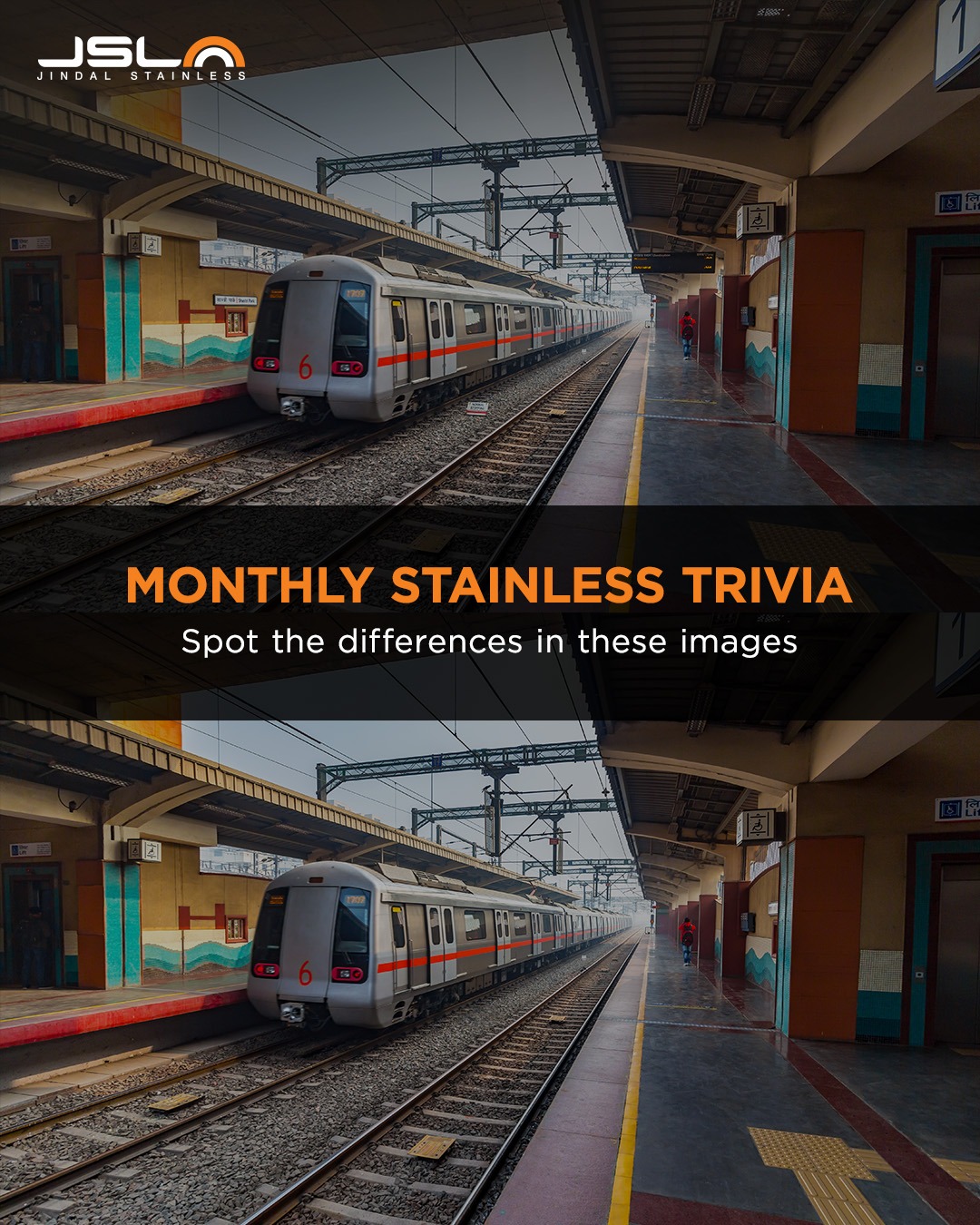

Monthly

Stainless Trivia

Fill in your answer below

Overview

Precision strips

Precision strips are formed via a cold rolling process & they offer attractive features such as:

- Accurate control over the strip dimensions (tolerances can be controlled in micron levels),

- Ability to manufacture low sheet thickness of up to 50 microns

- Obtaining an excellent surface finish.

The major thrive is to ensure defect-free strips, exhibiting low material property variations from the center to the edges of the strip. These can be manufactured in different grades depending on the desired application.

Coin Blanks

Jindal Stainless has been supplying stainless steel coins blanks to the Indian and international mints for making coins. The Company has the capability to produce high quality stainless steel and non-ferrous coin blanks. The present installed capacity for coin blanking is 10,000 metric tonnes per annum.

Process:

Blanking: The process involves punching pieces in specific shapes from sheets or strips. The punched-out piece is called the “blank,” hence the name “Blanking.” It is most often performed with tools made from hardened steel or carbide, which work on metals like Cupronickel alloys, Brass, Nickel Brass, Aluminium- Nickel Bronze, Ferritic stainless steel, etc.

Rimming: The rimming operation is carried out to raise the edge rims on the blank to form a “Coin Blank”.

Manufacturing:

- A strip of metal having a precise thickness is fed into a blanking press, which cuts blank disks of the required diameter.

- These blanks are deburred & cleaned.

- Edge rimming is done to achieve the required blank dimensions.

- Press-fitting of blanks of different diameters is done according to the currency requirements.

- The coin blank sample undergoes a series of annealing, descaling & polishing operations in order to achieve the required surface finish.

- Auto-inspection & weight check is performed on each coin blank before it is bagged & shipped.

Razor Blades

Razor blade cold rolled strips of up to 0.076 mm thickness are produced in Company’s Special Products Division (SPD) at Hisar and are supplied to leading Indian and international razor blade manufacturers.

FEATURES

Precision Strips

Excellent geometry precision- minimal thickness and width tolerances, flatness & straightness

Carefully designed microstructure

Free from harmful non-metallic inclusions

Good mechanical properties

Excellent surface finish

Best flatness metrics – ripple-free slit edges

Ready to be further fabricated - punching, stamping, embossing, etc. can be easily done on these precision strips.

Touch-free automated packaging

Frequently Asked Questions

What is the speciality of stainless steel?

+The speciality of stainless steel lies in its exceptional corrosion resistance, strength, and aesthetic appeal, primarily due to its composition of iron, carbon, and chromium.

The speciality of stainless steel is that these products are made to cater to the specific needs of the customers. The differentiation includes the metal chemistry, grades and ability to resist various industrial conditions.

Is stainless steel a specialty?

+Yes, stainless steel is considered a speciality alloy due to its unique properties, including high resistance to corrosion, strength, and adaptability across various industries.

The specialty stainless steel caters to the requirements of high precision and critical applications and so these are called specialty stainless steel.

How do I choose the right specialty stainless steel product for my needs?

+Selecting the right specialty stainless steel product depends on factors such as specific environmental conditions, required strength, corrosion resistance, and intended application. Our experts at Jindal Stainless can guide you in choosing the best solution for your project.

What is special quality stainless steel?

+Specialty stainless steel products refer to stainless steel that is manufactured to meet specific technical standards, offering enhanced performance in areas like corrosion resistance, strength, and wear resistance.

Read More

Explore Our Range of Speciality Stainless Steel Products

At Jindal Stainless, we offer an extensive range of speciality stainless steel products designed to meet the most demanding requirements across diverse industries. Our speciality products stand out for their superior strength, corrosion resistance, and adaptability. They are ideal for applications in varied sectors like automotive, electronics and telecommunication, consumer durables, petrochemicals, and many others. With a commitment to precision and innovation, we continue to set industry benchmarks by delivering high-quality stainless steel products for your industry needs.

Why Choose Jindal Stainless for Speciality Stainless Steel?

Choosing Jindal Stainless as your supplier for speciality stainless steel products ensures unmatched quality, reliability, and performance. Our long-standing reputation as industry leaders is built on a foundation of advanced manufacturing techniques, stringent International quality control measures, and a commitment to sustainability.

We prioritise innovation, customisation and flexibility to meet the evolving demands of modern industries, providing solutions that enhance productivity and longevity. Whether for highly technical applications or everyday industrial use, Jindal Stainless delivers durable and versatile stainless steel products that offer exceptional value.

Exceptional Speciality Stainless Steel Products for Every Need

Our speciality stainless steel products are designed to cater to a wide range of industries and applications. From the automotive industry, where durable materials are crucial, to petrochemicals, where corrosion resistance is essential, Jindal Stainless provides the ideal solutions. Our speciality stainless steel products in food processing maintain purity and integrity under extreme conditions, ensuring long-lasting performance. These versatile products are designed to excel in specific, high-performance environments, making them an indispensable choice for engineers and manufacturers worldwide.

Leading Speciality Stainless Steel Manufacturers

As one of the world’s leading speciality stainless steel manufacturers, Jindal Stainless is dedicated to producing high-quality stainless steel products that adhere to international standards. Our cutting-edge production facilities enable us to deliver precision-engineered stainless steel products that consistently meet the most rigorous demands of various industries. Whether you need stainless steel for harsh chemical environments, high-temperature applications, or other industry specifications, we ensure reliability in every step of the manufacturing process.

Key Features and Advantages of Speciality Stainless Steel Products

Jindal Stainless’s range of speciality stainless steel products offers numerous features that make it stand out amongst competitors. These products are designed to provide exceptional strength, corrosion resistance, and durability, ensuring long-lasting performance in challenging environments.

Superior Corrosion Resistance and Durability

Our speciality stainless steel is renowned for its outstanding corrosion resistance, making it suitable for use in industries where exposure to moisture, chemicals, or extreme temperatures is common. This property not only enhances the durability of our products but also reduces maintenance costs, making them a cost-effective choice for long-term applications. Our products are ideal for environments with critical reliability and rigidity, ensuring superior performance in all conditions.

Custom Solutions for Specific Applications

At Jindal Stainless, we understand that every industry has its unique challenges. That’s why we offer different solutions to meet specific application requirements. Whether you need enhanced corrosion resistance, a particular finish, or a specific thickness, we work closely with our clients to deliver stainless steel products that fit seamlessly into their projects. This flexibility allows us to provide solutions that cater to diverse industries.

Different Speciality Stainless Steel Products Produced at Jindal Stainless

Precision strips

Precision strips are a speciality stainless steel product manufactured by Jindal Stainless through a cold rolling process. They are highly valued for their precise dimension control, with tolerances achievable at the micron level and the ability to be produced with extremely low thicknesses down to just 50 microns. They also boast an excellent surface finish, making them aesthetically appealing. The primary focus during manufacturing is to produce defect-free strips that show minimal variations in material properties from the centre to the edges. Available in various grades, precision strips are tailored to meet specific application needs, ensuring both functionality and quality.

Coin blanks

Jindal Stainless is a key supplier of stainless steel and non-ferrous coin blanks to mints worldwide. We specialise in producing coin blanks through a process that includes blanking, where shapes are punched from strips to create blanks, followed by rimming to add edge rims. The manufacturing procedure also involves cutting to size, deburring, cleaning, and edge rimming. After achieving precise dimensions, the blanks are annealed, descaled, and polished for the desired surface finish. Each coin blank undergoes auto-inspection and weight verification before being packaged for delivery, ensuring high-quality standards for minting purposes.

Razor blades

Jindal Stainless manufactures razor blade cold-rolled strips with a finesse of up to 0.076 mm thickness. These precision-engineered strips are supplied to premier razor blade manufacturers both in India and across the globe. This product stands as a testament to our capability to produce highly specialised stainless steel products that cater to specific industry needs, maintaining a standard of quality that meets global demands.