Mr R S Choudhary

June 24, 2021

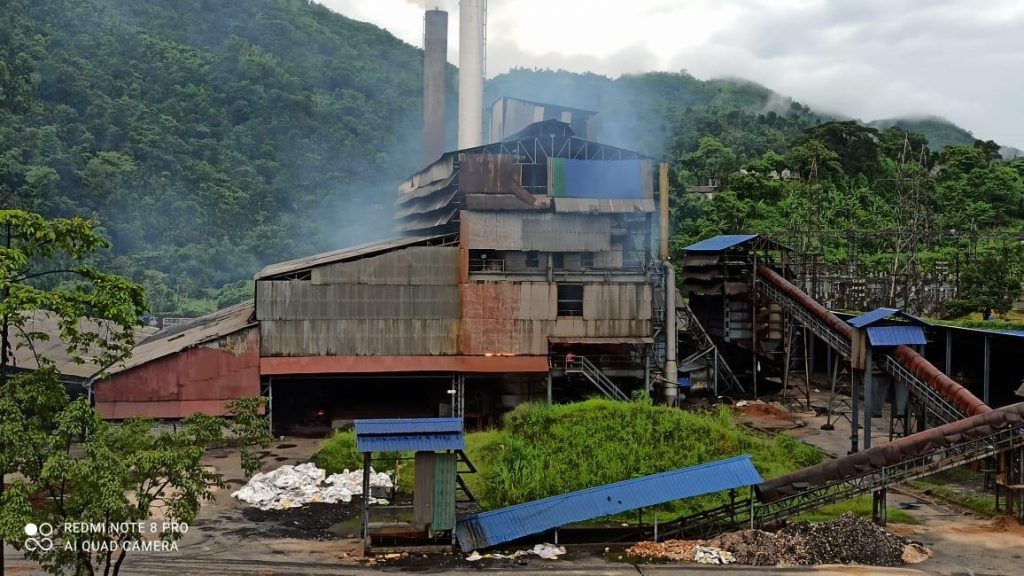

We proudly present to you our Star Supplier, Nalari Ferro Alloys Pvt Ltd. A major supplier of ferro-alloys and Low Ash Metallurgical (LAM) coke, the Meghalaya-based firm is a trusted partner of Jindal Stainless that undertook far-reaching in-house steps to improve quality and delivery during the pandemic, thus propelling growth for the Company. Stainless Post interviews General Manager, Nalari Ferro Alloys Pvt. Ltd., Mr Ram Swarup Choudhary and brings you the story of his team’s untiring efforts and dedication.

Tell us about your journey at Nalari Ferro Alloys Pvt. Ltd.?

Initially, into coal business, we started a Low Ash Metallurgical (LAM) coke plant in Guwahati in the year 2000. Later, eyeing a significant potential, we entered the ferro alloys industry in 2002. In the year 2003, we established Nalari Ferro Alloys Pvt. Ltd. in Meghalaya. Soon, we also established our presence in the cement and automobile industries, apart from lam coke and ferro alloys.

Coming from my hometown in Rajasthan with a commerce degree, I joined the organisation in 1999. In my current role as the General Manager, I am responsible for the overall operations of the organisation.

What are the major challenges in your line of business?

It is a known fact that the international raw material trends are often dynamic. Moreover, in a globalized industry, the prices of finished products are directly linked to the globalized raw material prices and international stainless steel prices. For this reason, we are often faced with the challenge of managing the fluctuations in supply chain and plan the current as well as future operations. Experience has been my teacher in these 20 years of service in the industry. I’ve been able to develop healthy business relationships with major players like Jindal Stainless only on the basis of commitment and on-time delivery.

What are the notable advancements that you brought in order to be the Star Supplier?

Some major steps taken are as follows-

- We tried to mitigate the sizing issues by installing five vibrating screens that helped check material before packing to ensure any sizing errors.

- We ensured the best quality by in-person attending and understanding the customer’s concern regarding slag touch material. We changed our process and adopted a washing and draining system that reduces slag production. We enforced lot-wise chemical analysis of incoming raw materials. We maintained furnace wise tapping records and identified jumbo bags with 1 MT low carbon ferro-silicon (as per license IS 1110). We carried out wet/chemical analysis in a documented procedure and implemented the best operating procedure to control solidification and achieve best metallurgical properties for low carbon ferro-silicon.

- We always maintained the carbon content as prescribed by the customers. However, we further reduced it by controlling our processes further.

- During the nation-wide lockdowns during the pandemic, timely transportation was an issue. However, we made sure that our customer faces no delays in their deliveries.

- We readily accepted customer’s suggestion of implementing new processes and update them. We made sure that we bring in the process, quality, and environment related suggestions of the customer on the table and act swiftly to enforce them.

- We received guidance on technical know-how and assistance on how to keep records, create efficient SOPs, procedures and manuals. We even visited the plant premises to get a better idea of the customer’s need.

When and how did your journey with Jindal Stainless begin? What do you think sets it apart when compared to other suppliers?

We have been associated with Jindal Stainless since 2010 and continue to ensure the best supply of ferro silicon in terms of quality, delivery, and response to both the plants of the Company. It offers us good quantum of material requirement and a workable operational cycle. The teammates are cordial and always support us. For several years, we have been satisfied with the ease of doing business with Jindal Stainless.

What is your message to the young managers out there?

I am a family man and I draw a substantial amount of energy from my three kids. I work hard to ensure a secure and successful future for them. I hope for them, and for several other young leaders to work hard and be motivated in their journeys. And in return keep motivating us to strive harder.