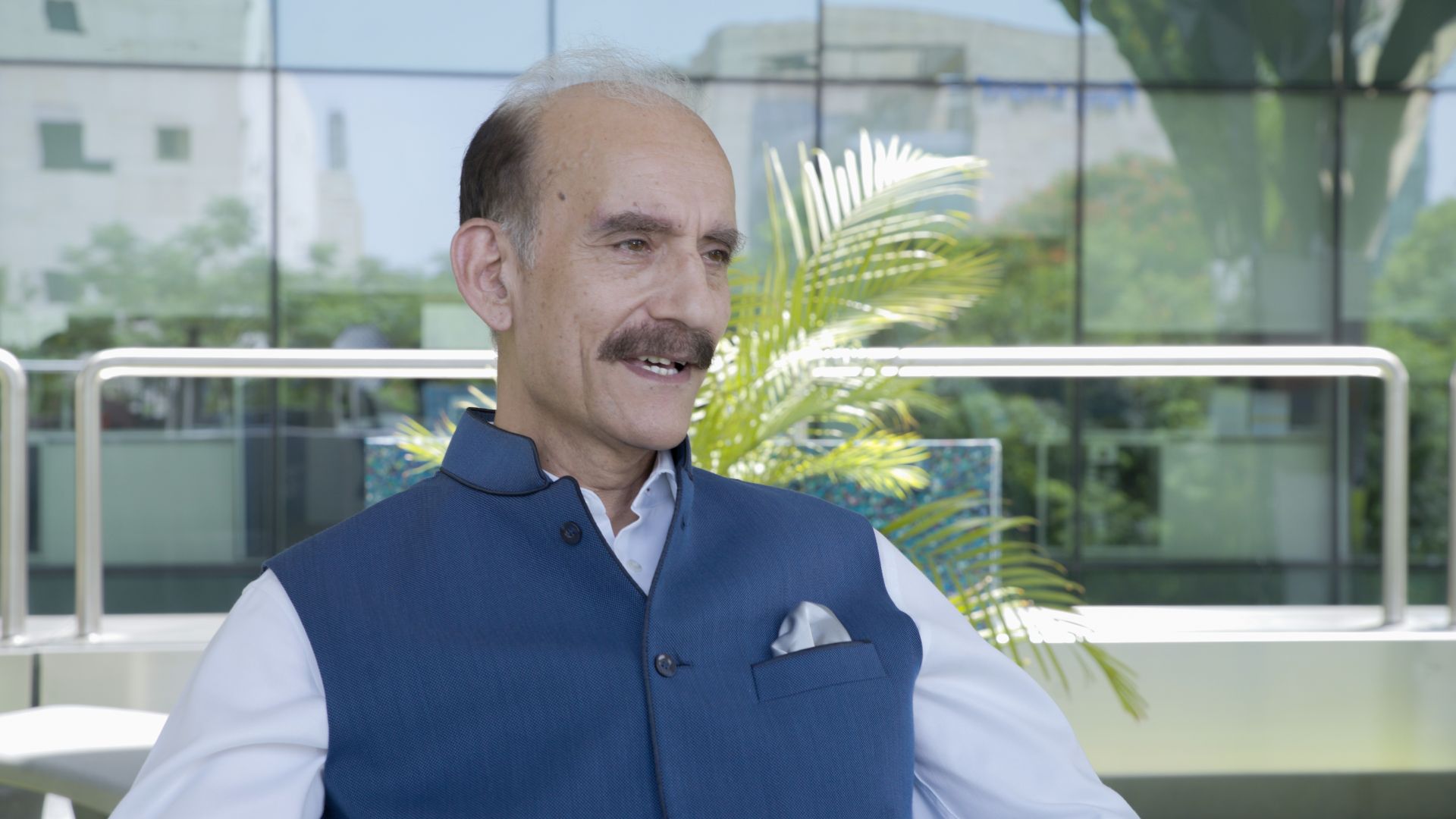

Mr Prakash Sanghvi

March 29, 2018

Read the life-story of the reclusive Chairman & MD of Ratnamani Metals and Tubes Ltd who joined us for an exclusive and candid talk.

From a small-scale trader to the market leader, meet the man who turned-around the fate of stainless steel industry with his awe-inspiring journey.

Tell us about your journey so far.

Chairman & MD of Ratnamani Metals and Tubes Ltd

It all started in 1974 when I joined my family trading business. We used to trade stainless steel (SS) and other metals and sell them locally in Mumbai to the end-user industries. It was only after a decade’s travail that my brother and I decided to spread our wings to soar higher. That’s when in 1983, we incorporated Ratnamani Metals & Tubes Pvt Limited, our very own manufacturing unit to produce SS tubes and pipes- both welded and seamless. Within no time our native flight expanded and we had two small units of our own, RTIPL & RM&TL. Our consistent efforts towards providing quality products at competitive prices, coupled with timely delivery, brought us all the fame and respect we had dreamed of. In 1993, we went full throttle and listed ourselves on regional courses, BSE. And then there was no looking back.

However, I knew deep inside my heart that the path I am heading towards is more challenging than acclaimed. It required persistence and innovation of the highest order, but when they both conjoined, the results were profound- some of them included a new LSAW Plant, a new mobile plant for large diameter water pipelines, and a new green field plant at Kutch with an expanse of over 140 acre land to set up a world-class integrated stainless steel hot finish pipes, stainless steel welded pipes and carbon steel ERW & SAW pipes, with 3LPE coating plant. Today, we are exporting to around twenty countries, including Japan, Korea, Singapore, Indonesia and Gulf countries. We are the only Indian company in the gulf, approved by Saudi Aramco and SABIC, for exporting stainless steel tubes and pipes. And we happily introduce ourselves as India’s largest SS tubes and pipes manufacturer.

What were the major challenges like?

Every ride has its own jerks and it is never as easy as it appears. Our major challenge has been the very nature of our business which is highly project-oriented. Even though there is an extensive range of grades, finishes and customizations we offer to industries like Oil and Gas, Petrochemical and Refineries, Chemical & Fertilizers, Power Plants etc, the cyclical nature of these businesses impacts our trade to a large extent and we have no hold over this. With the Replacement and Maintenance market being only 15-20%, there is less scope for stock and sell items; with 80% being make-to-order products only. Periods like 1997-98 and the Lehman Brothers’ crisis, the market observed steep downward trend. But despite all that, with partners like Jindal Stainless, we could sustain and recover easily.

Would you like to share the secret of your success?

The principle that keeps Ratnamani floating is based on the cordial relationship of the company with its employees and other partners. People have bestowed their trust upon us and now it is our responsibility to uphold it. Moreover, our employee-employer quotient is very strong. Most of our people have been with us since the inception of the company, and to incentivise them, we have given them ESOPs. With such a positive and spirited team of employees, we have made ourselves known as one of the most innovative companies in the industry.

Innovative business practices are yet another reason for how we have come this far. Every second year we add a new value-added product or engage in producing some import substitute, like we recently did for nuclear application. It is indeed a notable achievement that we indigenously supplied the moderator reactor tube for Brahmos missile which was earlier being imported from Russia.

Now that you been in business for decades, what are some notable trends you have adopted?

Go with the flow- that’s how we have enhanced ourselves. With new developments in technology, we have completely upgraded our equipment and machinery. To ensure quality output, we perform several quality control checks and carry out numerous tests like eddie current test, hydro test, and ultrasonic X-Ray test in-house, as our products go in use for critical applications. We spend more hours in inspection and quality procedures than manufacturing, because each tube is a product for us and any quality failure will be a big loss to our customer.

In your entire gamut of suppliers, what sets Jindal Stainless apart?

We have very cordial relations with Jindal Stainless. The promoters are very humble and we have shared a good rapport with them from the time JSL established its foothold in the market. Today, the company is well managed by professionals. People across the hierarchy are very cooperative and we are able to interact with them candidly. If our effort is to procure raw material locally from India, then it has to be from Jindal Stainless. We are always exchanging ideas on quality with them; I must commend the team on their amazingly high proactiveness, which leads them to promptly react and improve upon shortcomings, if any. We have been growing our business by increasing our engagement with them, and that’s what any association should aim to do. In our trade, raw material cost constitutes 60-65 % of the entire production cost, so we always try to procure raw material locally, as it gives us an edge over imports. And for us, the best available source for procuring material locally is always Jindal Stainless.

What is your message to young managers?

I would like to emphasise that honesty is the best value one can have and we all should inculcate it in us, not just for our work but also for our own satisfaction. Things will come to you naturally if you are honest and have imbibed good values and ethics. Secondly, a combination of hard and smart work is essentially important, because there is no substitute for either. And the third and most important advice is that we should all focus on our strengths and do what makes us happy, only then will we be able to find the best in us.