7 Benefits of Stainless Steel: Why It is the Perfect Choice

October 28, 2024

Introduction to Stainless Steel

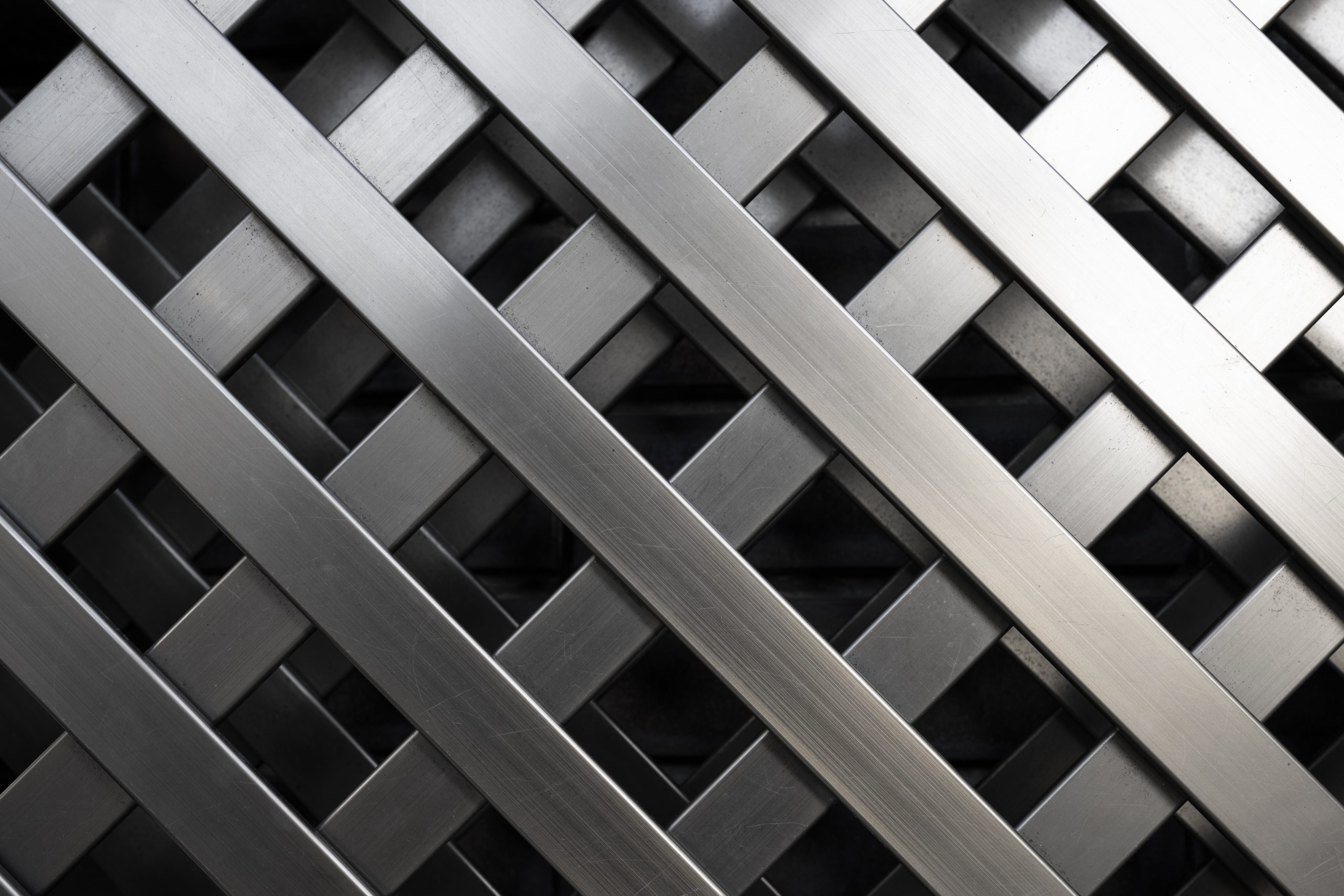

From modern engineering to architectural design, stainless steel consistently stands out as a top-tier material choice in every industry due to its versatility and durability.

The rising dependency on this alloy in various sectors highlights its potential and the multiple benefits of stainless steel. Its application in projects ranging from tall skyscrapers to complex transportation systems as well as medical applications indicates its crucial role in modernisation and economy.

Stainless steel provides numerous benefits, making it an excellent choice for a wide range of applications. The stainless steel pros not only extend to its exceptional physical properties but also its cost efficiency and environmental friendliness. The key reasons for its popularity are its capacity to resist corrosion, sustain severe temperatures, and maintain integrity under physical stress, making it a perfect material for ambitious and innovative infrastructure projects.

Understanding Hot And Cold Rolling Processes

To understand the benefits of stainless steel, it is necessary to understand the two processes that shape the ‘metal of the future – hot rolling process as well as the cold rolling process. Let us guide you through and explain both the crucial processes that make stainless steel versatile and robust.

These techniques are vital in enhancing the properties of stainless steel, enabling its use in a wide array of applications, from heavy-duty industrial components to delicate consumer goods. Both hot and cold rolling processes are crucial in improving the strength, formability, and surface finish of stainless steel, making it suitable for varying operational environments.

What are Hot And Cold Rolling Processes:

The hot rolling process involves heating stainless steel above its recrystallisation temperature, typically between 900°C and 1200°C, before passing it through rollers. This high-temperature environment allows the steel to be shaped and thinned without compromising its structural integrity. Hot rolling significantly enhances the steel’s ductility, allowing for larger deformation without fracturing. This method is ideal for producing large-scale products such as plates, beams, and coils that require strength and toughness.

Cold rolling, on the other hand, occurs at room temperature and is used to produce a smoother, more polished finish. After the steel undergoes the hot rolling process, it is further processed through cold rolling to achieve more precise dimensions and a refined surface. Cold rolling increases the steel’s strength through strain hardening and enhances its surface finish, making it ideal for applications that require both aesthetic appeal and mechanical precision, such as automotive parts, kitchen appliances, and construction materials.

Hot And Cold Rolling Processes and Their Importance:

The hot rolling process is essential for applications where material toughness and durability are paramount. It provides the foundation for producing robust steel products that can withstand harsh conditions, high pressures, and extreme temperatures, making it a preferred choice in industries like construction, shipbuilding, and energy production. Hot rolling improves grain structure, which enhances the steel’s resistance to wear and corrosion, ensuring longevity in demanding environments.

Cold rolling, while improving mechanical properties, plays a key role in delivering a superior surface finish. It is essential for applications where both visual appeal and precision are critical. Cold-rolled stainless steel products often exhibit higher strength, tighter dimensional tolerances, and a smooth, shiny finish, making them suitable for use in the manufacturing process of precision-engineered components and consumer goods.

7 Key Benefits of Using Stainless Steel

Superior Durability:

Stainless steel is engineered to endure. Its tremendous strength makes it extremely resistant to wear and tear, which is crucial in settings where materials must withstand heavy usage and extreme conditions. The benefits of using stainless steel in constructing infrastructure are evident in its ability to maintain integrity over time without deforming or breaking, reinforcing its standing as a fundamental building block in modern engineering.

Corrosion Resistance:

One of the most important stainless steel pros is its high resistance to corrosion, which ensures longevity and reliability, particularly in harsh and coastal environments where oxidation and corrosion rates are accelerated. Stainless steel’s corrosion resistance underpins its extensive use in marine, industrial, and urban settings, protecting investments against the ravages of environmental stress and chemical exposures.

Low Maintenance:

Another benefit of using stainless steel is its minimal maintenance requirement. The non-porous surface of stainless steel makes it easy to clean and disinfect, reducing upkeep costs and effort. This characteristic is particularly beneficial in industries where hygiene is paramount, such as in food processing plants and hospitals.

Aesthetic Appeal:

Stainless steel pros do not only include practicality but also aesthetic appeal. Its sleek, modern finish can seamlessly integrate into various architectural styles, making it an ideal choice for visible structural elements that require both functionality and style. This dual benefit of stainless steel enhances its appeal in architectural and consumer durable product design, offering both durability and beauty.

Recyclability and Sustainability:

In today’s eco-conscious world, the recyclability of materials is crucial. Stainless steel answers the call for sustainability as it is 100% recyclable. The recycling process of stainless steel is efficient, with a significant proportion of new stainless steel coming from old re-melted stainless steel scrap, thus contributing to a circular economy and reducing environmental impact.

Heat Resistance:

Stainless steel’s ability to resist high temperatures is a crucial feature in applications involving extreme heat. This heat resistance ensures performance and structural integrity under high-temperature conditions, making stainless steel an indispensable material in the manufacturing, energy, and automotive industries.

Cost-Effectiveness Over Time:

While the initial cost of stainless steel might be higher than some other materials, its long-term value is unparalleled due to its durability, low maintenance requirements, and resistance to a wide range of environmental factors. This translates into reduced lifecycle costs, making stainless steel a wise investment for applications demanding longevity and minimal upkeep.

Why Stainless Steel is the Perfect Choice

In today’s material science and engineering world, material selection is essential for the success of any project. Stainless steel stands out as an excellent choice for a wide range of applications and sectors, thanks to the unparalled benefits of using stainless steel. This material not only meets the rigorous demands of modern infrastructure but also addresses environmental considerations and economic concerns with remarkable efficiency. Stainless steel pros including aesthetic variety and ability to withstand severe temperatures without losing strength make it an essential material for building strong, long-lasting, and efficient structures.

Conclusion

The benefits of using stainless steel are compelling and multidimensional, making it the optimal choice for a diverse range of applications. Its durability, corrosion resistance, low maintenance requirements, aesthetic appeal, sustainability credentials, heat resistance, and cost-effectiveness converge to elevate stainless steel beyond a mere material option to a strategic investment in the future of infrastructure.

With the benefits of stainless steel in your projects, you leverage a material that is synonymous with resilience, efficiency, and innovation. This choice not only aligns with the objectives of constructing more durable, sustainable, and cost-effective infrastructure but also showcases a commitment to pioneering practices that will define the future of global development.

In bridging technical excellence with visionary application, stainless steel emerges not just as a material of choice, but as the cornerstone for constructing safer, more resilient infrastructure that stands the test of time. Choose the benefits of stainless steel with Duplex Stainless Steel, and invest in a legacy of quality and reliability.