Monthly

Stainless Trivia

Fill in your answer below

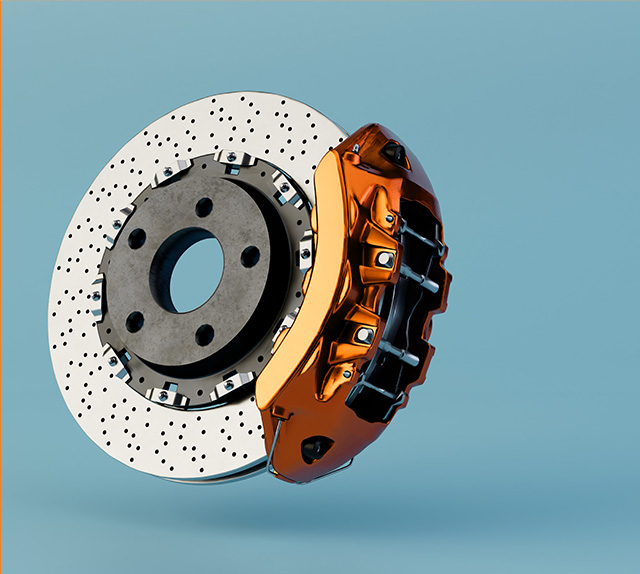

Disc Brake

Which grade of SS does Jindal Stainless supply?

Jindal Stainless supplies the grade 410DB used for the disc brake application of two-wheelers and is the leading supplier to two-wheeler manufacturing companies in India.

With supreme quality and trust among consumers, Jindal Stainless has developed a sense of safety for the vehicle and the people of India.

What are the benefits of using stainless steel in disc brakes?

The material for a brake disc of a two-wheeled vehicle, etc., is required to have properties such as abrasion resistance, rusting resistance, and toughness. Hardness is an important factor for disc brakes and stainless steel 410DB grade plays an important role in achieving the desired hardness for disc brake application. It is available in various thicknesses which makes it the most suitable product for different-capacity engine vehicles.

It, therefore, exhibits a superior combination of high strength, ductility, formability, and toughness compared to other metals and alloys, and the intrinsic weight of the vehicle decreases, making stainless steel a perfect fit for disc brakes.

Role of disc brakes in the automotive industry

The automotive and transport industry is one of the largest industries in the world and India provides a good percentage of consumers to it. Over the last decade, the need to travel has increased owing to numerous reasons. This has led to the growth and expansion of the automotive and transport industry manifolds.

While there are various kinds of vehicles today, a common product that binds most of them is the brake. Brakes are the most important safety system in any vehicle as they provide the ability for a vehicle to slow down or stop in an instant, thereby avoiding an accident.

Disc brakes, a type of brake, is used for instant braking and locking of the vehicle. The disc brakes were developed in England in the 1890s and were adopted in nearly every vehicle by the late 1920s. They are a critical part of auto safety systems as they offer better-stopping performance in vehicles as compared to drum brakes. Disc brakes cool rapidly and have longer life as compared to drum brakes.

Over the years, different materials have been used to make disc brakes. However, after countless experimentations, stainless steel has emerged as the clear winner as an ideal fit. Stainless steel is a very good option for making disc brakes as it can be used to form a disc brake rotor which has several excellent properties even when the steel is hardened with a cooling speed slower than air cooling.

Why choose Jindal Stainless?

Jindal Stainless has been in the stainless steel industry for more than 50 years and is always known for its quality. It is India's largest manufacturer of stainless steel in 200, 300, 400, and duplex grade stainless steel products. The company has witnessed and contributed to the growth of the automotive industry in India, especially in vehicular exhausts, fuel tanks, and disc brakes.