Monthly

Stainless Trivia

Fill in your answer below

Features

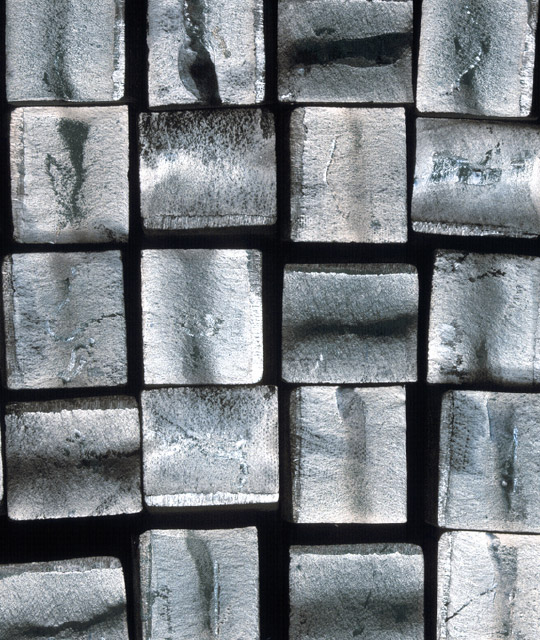

Blooms manufactured through the continuous casting route provide a better advantage in further rolling operations when compared to other conventional casting processes, in terms of their unidirectional solidified microstructure, in turn, they provide better properties when compared to the other casting processes.

Blooms are cost-effective and have significantly reduced manufacturing time compared to conventionally cast stainless steel ingots.

Blooms can be transported very easily.

Blooms are cast from twin stand bloom caster at steel melt shops. Liquid steel is produced through electric arc furnace-AOD convertor/VOD-ladle refining furnace route.

Size: 160 mm sq.

200 mm sq.

260 x 200 mm