Jindal Stainless develops Superior Machinable stainless steel grade 316F

August 3, 2022

Jindal Stainless R&D team had recently interacted with one of the premium customers to understand the key basic requirement of enhanced machinability of 316 grade in pulp & paper component manufacturing and catered with SS 316F ( Sulphur 0.2%) where in the customer’s key requirement was of longer tool life with higher cutting speeds. The customer was earlier importing the entire component for paper and pulp industry.

After sustained R&D efforts, we are proud to have indigenously developed and manufactured grade 316F stainless steel in sheet and plate form.

Grade 316F, commonly termed as free-machining austenitic stainless steel, contains high sulphur (0.2%S) as an alloying element. This grade also contains Mo for improved pitting corrosion. Sulphur along with manganese forms the manganese sulphide (MnS) compound, which causes chip-off more readily while machining.

316F finds its application where material with high machinability is required. Wear and tear of tools is almost 41% lower in comparison to SS 316L when compared with SS 316F.

The grade is majorly used in fabrication of various component involving machining typical used in various process industry segment (Food & Beverage, Pharmaceutical, Pulp & Paper, Fertilier etc) and pharmaceutical processing equipment, marine exterior trim and industrial equipment that handle the corrosive process chemicals used to produce inks, rayons, photographic chemicals, paper, textiles and bleaches.

| Machining Parameters | Characteristics | 304L | 316L | 316F |

| Spindle Speed: 400 RPMCutting Speed: 100 m/min Depth of cut: 2 mm |

Chip Geometry |

|||

| Longer helical chips segments | Longer helical chips segments | Smaller spiral segments | ||

| Surface Roughness Ra (µm) | 3.4 | 3.9 | 2.5 | |

| Tool Wear (μm) | 93 | 132 | 63 | |

Spindle Speed: 200 RPMCutting Speed: 50 m/minDepth of cut: 1 mm |

Chip Geometry |

|||

| Smaller spiral segments | Longer helical chips segments | Smaller spiral segments | ||

| Surface Roughness Ra (µm) | 2.8 | 3.6 | 1.8 | |

| Tool Wear (μm) | 39 | 48 | 28 |

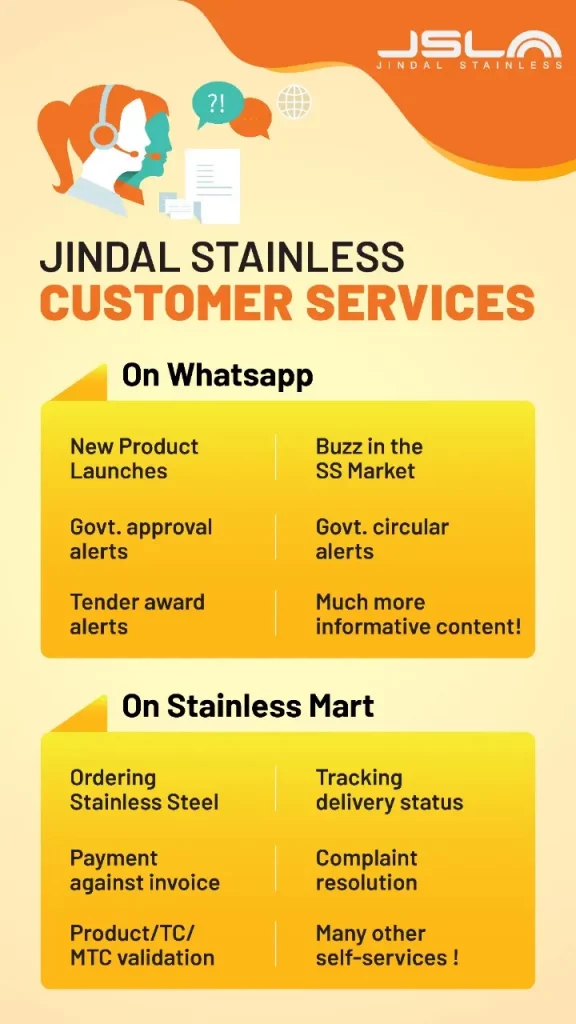

Link to access our self-service e-commerce portal

https://stainlessmart.jindalstainless.com/login

For any product/order enquiry, please reach out to our sales leaders mentioned below:

| Region | Name | Email ID | Tel |

| All regions | Mr Devender Devgun | devender.devgun@jindalstainless.com | +91-8800699454 |