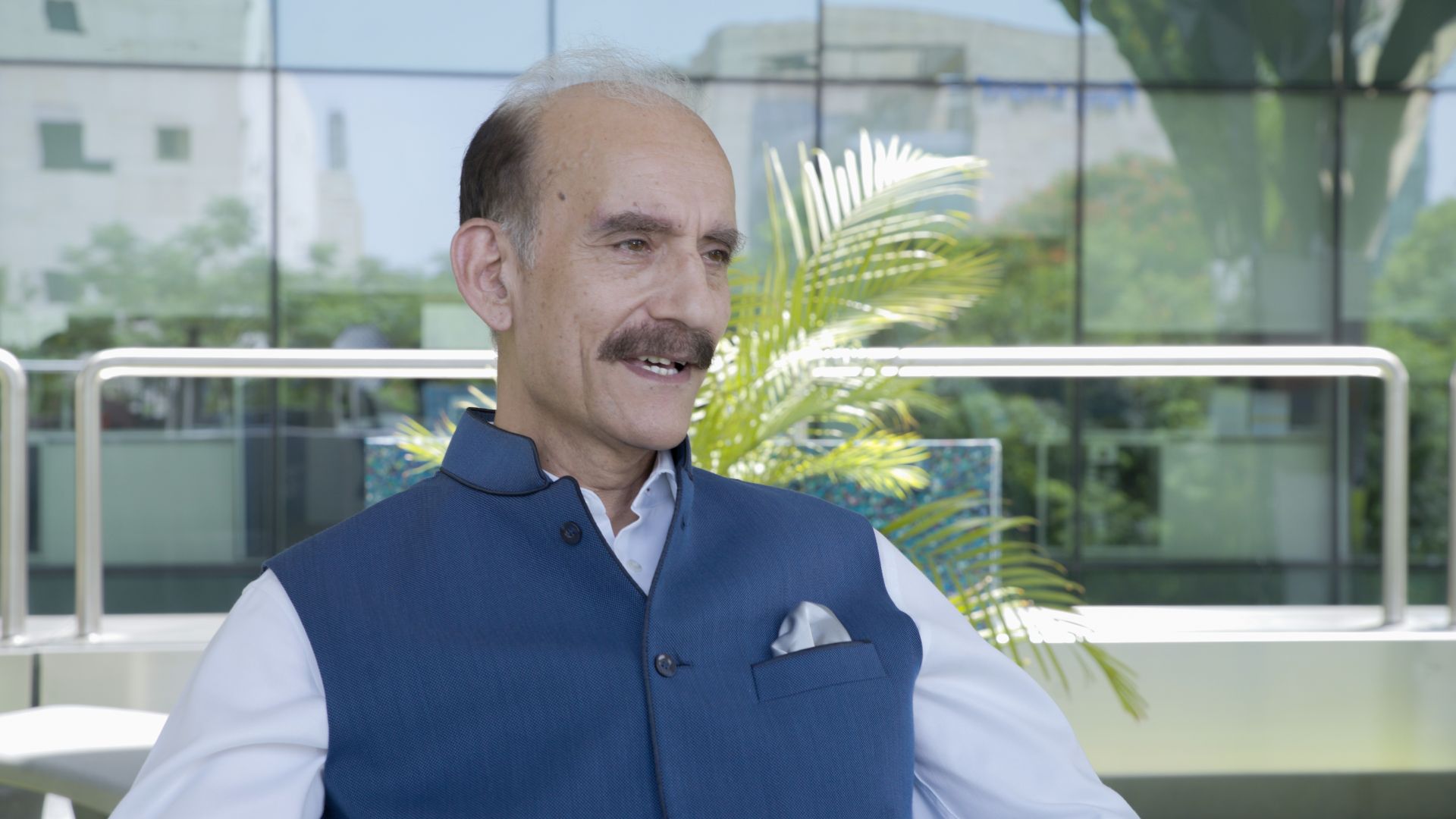

Mr Max Rossigneux

July 26, 2022

Presenting a cherished customer in this edition, Monnaie de Paris! An industrial and commercial public French establishment, Monnaie de Paris is a state public service that manufactures the French national currency. As a brand image, a museum and an artistic creation venue, Monnaie de Paris has been instrumental in developing and sustaining the French spirit across the world. Stainless Post interviews Director, Purchasing, Monnaie de Paris, Mr Max ROSSIGNEUX.

Tell us about your journey so far.

I was born in Africa where I lived for 18 years. I used to travel to different parts of the world with my parents, something that I still reminisce. Since childhood, I was fascinated by Asian Arts and I used to purchase them for my personal collection from every new place I explored with my parents.

I spent a decade working at Galeries Lafayette, France’s biggest departmental store. There, I headed the houseware division and gained insights in consumer behaviour and purchasing. Post my tenure at Galeries Lafayette, I entered the cookware and flatware industry, the major market for stainless steel. This stint further familiarized me with the consumer goods industry and also helped me develop an understanding of the benefits of using stainless steel. Later, in, I joined the revered French mint, Monnaie de Paris, which is one of the world’s oldest and continuously running enterprises. My objective was to organize their purchasing division. Over the years, this department has evolved as one of the integral divisions of Monnaie de Paris.

What have been the milestones of Monnaie de Paris’ journey?

As one of the oldest French institutions, Monnaie de Paris has been minting coins since 1973, from the cutting out blanks to the final conditioning. On an average, the mint produces one billion coins every year, half of which is intended for export. Its annual turnover stands at nearly 146 million euros, with its annual purchasing turnover at nearly 90 million euros.

In my capacity as the Purchasing Director, I am involved in strategy-related decisions for the French mint. Our work requires us to tap into various verticals on a regular basis. An individual’s work is not restricted to just one division here. We may start our day by engaging with a Far East supplier for raw material, and later find ourselves juggling between managing packaging facilities, management, communication, marketing, and board meetings. This is exciting and challenging. Moreover, it helps us keep a track of the ongoing work efficiently.

When and how did your journey with Jindal Stainless begin? What sets us apart from others?

Our partnership with Jindal Stainless began in 2004 when we had stepped into the international coin business. Our collaboration with Jindal Stainless has been an important one that led to the success of our exports across Africa and Middle East. Over the years, Jindal Stainless has supplied more than 5,000 metric tonnes world-class coin blanks. Even today, while working on a project with Jindal Stainless, we are assured of the Company’s quality, prices, delivery schedule, shipments, etc. We share a mutually rewarding relationship with the Company, where Monnaie de Paris’ strong technical support and expert guidance has helped Jindal Stainless evolve its value-added products like shaped blanks, stainless steel rings, and edge-lettered blanks.

Your view on the coin blank industry and how it’ll shape up in the future?

The coin blank industry is complicated. This can be attributed to two facts- one, limited players supplying quality-conscious and customized stainless steel for producing a wide variety of coin blanks (mono-metallic, bi-metallic, alloy-based, edge-lettered, etc.). Two, an uneven demand cycle due to irregular minting capacities. However, the concentration of coins in the overall European context is bound to increase due to the unavailability of hard cash in Europe and other countries.