A Complete Guide to Reinforced Concrete Structures Using Stainless Steel

February 25, 2025

Introduction

When it comes to building structures that can withstand the test of time, the combination of concrete and rebar plays a vital role. Rebar, or reinforcement bar, significantly enhances the tensile strength of concrete, ensuring stability and durability in everything from bridges to skyscrapers.

Among the various types of rebar available, stainless steel stands out as a superior choice for reinforcing concrete, thanks to its exceptional strength and resistance to corrosion. This guide delves into why stainless steel is a game-changer in reinforced concrete construction, explores the different types of rebar, and shares best practices for installation to maximize structural integrity and longevity.

Why Choose Stainless Steel Rebars in Concrete Reinforcement?

Integrating stainless steel with reinforced concrete is an innovative solution that meets the demands of modern construction. Let’s explore the unique advantages of stainless steel rebars:

Superior Corrosion Resistance and Durability

One of the standout advantages of stainless steel rebars is their remarkable resistance to corrosion. Unlike traditional carbon steel rebar, stainless steel does not easily rust when exposed to moisture or harsh environments. This makes it an ideal choice for marine environments and areas with high humidity.

Enhanced Durability

Concrete structures reinforced with stainless steel rebar exhibit significantly longer lifespans. This enhanced durability reduces the frequency of repairs and maintenance, ultimately saving costs in the long run. It’s particularly effective in critical structures like bridges, tunnels, and skyscrapers.

Sustainability and Eco-Friendliness

Stainless steel rebars contribute to sustainable construction practices. Their long lifespan and recyclability make them an eco-friendly option. Using these rebars reduces waste and supports greener building initiatives.

Types of Rebar for Concrete Reinforcement

Choosing the right type of concrete rebar is essential for ensuring structural integrity. Here’s a brief overview of the common types:

Carbon Steel Rebar

Carbon steel rebar is the most widely used option in construction. It is cost-effective, offers decent tensile strength, but is prone to corrosion in moist environments. For reinforced concrete floors, concrete floor rebar is commonly used to enhance durability and structural integrity.

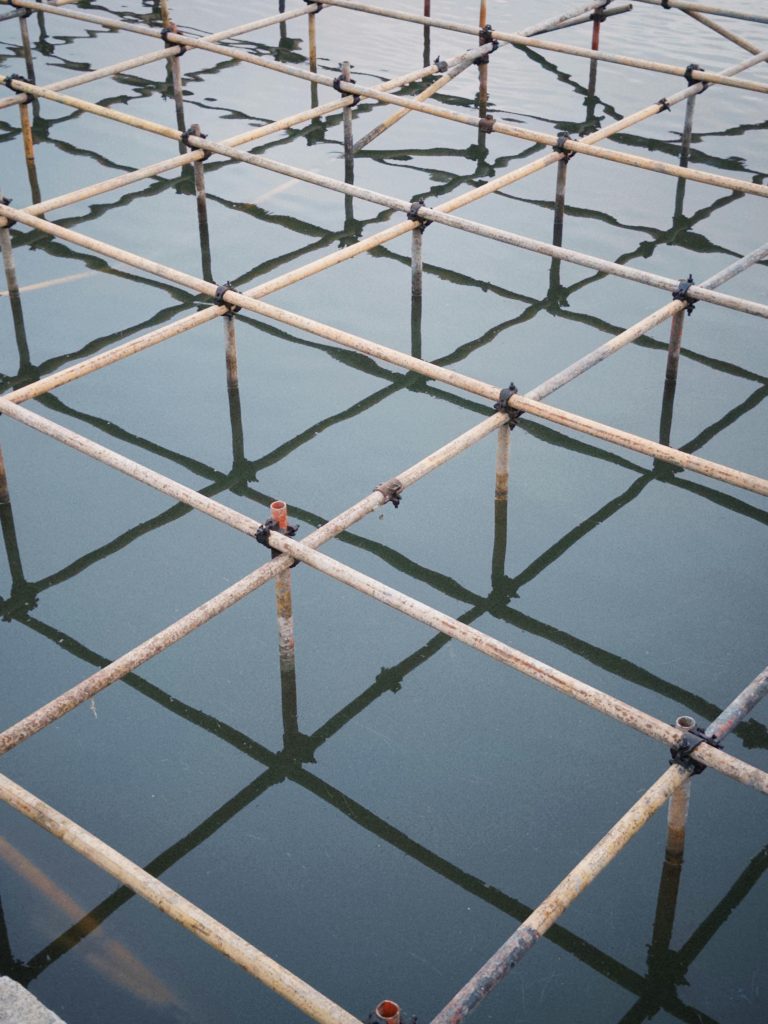

Welded Wire Fabric

Welded wire fabric, or wire mesh, reinforces slabs and pavements. It is often used in concrete floor rebar applications due to its ease of installation.

Epoxy-Coated Rebar

Epoxy-coated rebar is designed for enhanced corrosion resistance. However, the coating can be damaged during handling, reducing its effectiveness compared to stainless steel rebar. In applications such as concrete structures, concrete wall rebar is often used to ensure strength and resistance to environmental factors.

Step-by-Step Guide to Rebar Installation

Rebaring is the process of installing reinforcement bars into concrete structures to enhance their strength and durability. Here’s a step-by-step guide:

Preparing the Concrete and Rebar

Before installing a concrete stainless steel rebar, ensure that the concrete mix is prepared correctly and that the rebar is clean and free from rust or contaminants. Proper preparation is critical for achieving a strong bond between the concrete and rebar.

Placement Techniques for Concrete Stainless Steel Rebar

Accurate placement is vital. Rebars should be positioned according to the structural design and held in place using spacers or chairs. For projects like concrete wall rebar, vertical placement must be aligned with the blueprint. Similarly, when using rebar for concrete slab, proper spacing and positioning ensure even load distribution and structural integrity.

Installation for Different Applications

- Slabs & Floors: Rebars should be properly tied and spaced to prevent movement during the concrete pouring process.

- Walls & Vertical Structures: Ensure vertical rebars are correctly placed to support load-bearing walls and high-rise structures.

Conclusion

Integrating stainless steel and reinforced concrete is undoubtedly a step forward for construction, offering unmatched strength and reliability. The use of stainless steel rebars not only enhances corrosion resistance and durability but also supports sustainable construction. It is a cost-effective long-term solution for modern infrastructure.