Monthly

Stainless Trivia

Fill in your answer below

Introduction

Crude Oil Storage Tanks are critical infrastructure in the oil and gas industry, demanding robust materials that can withstand harsh environmental conditions. Traditionally, mild steel (MS) has been used for upper deck plates. However, challenges such as corrosion, frequent maintenance, and a shorter lifespan have necessitated a shift to better alternatives.

Stainless steel, specifically grade 409M, has emerged as a superior choice due to its exceptional corrosion resistance, durability, and low maintenance requirements. This case study explores the successful application of 409M stainless steel by Jindal Stainless Limited, replacing mild steel for the upper deck plates of crude oil storage tanks and setting a new benchmark in industrial material innovation.

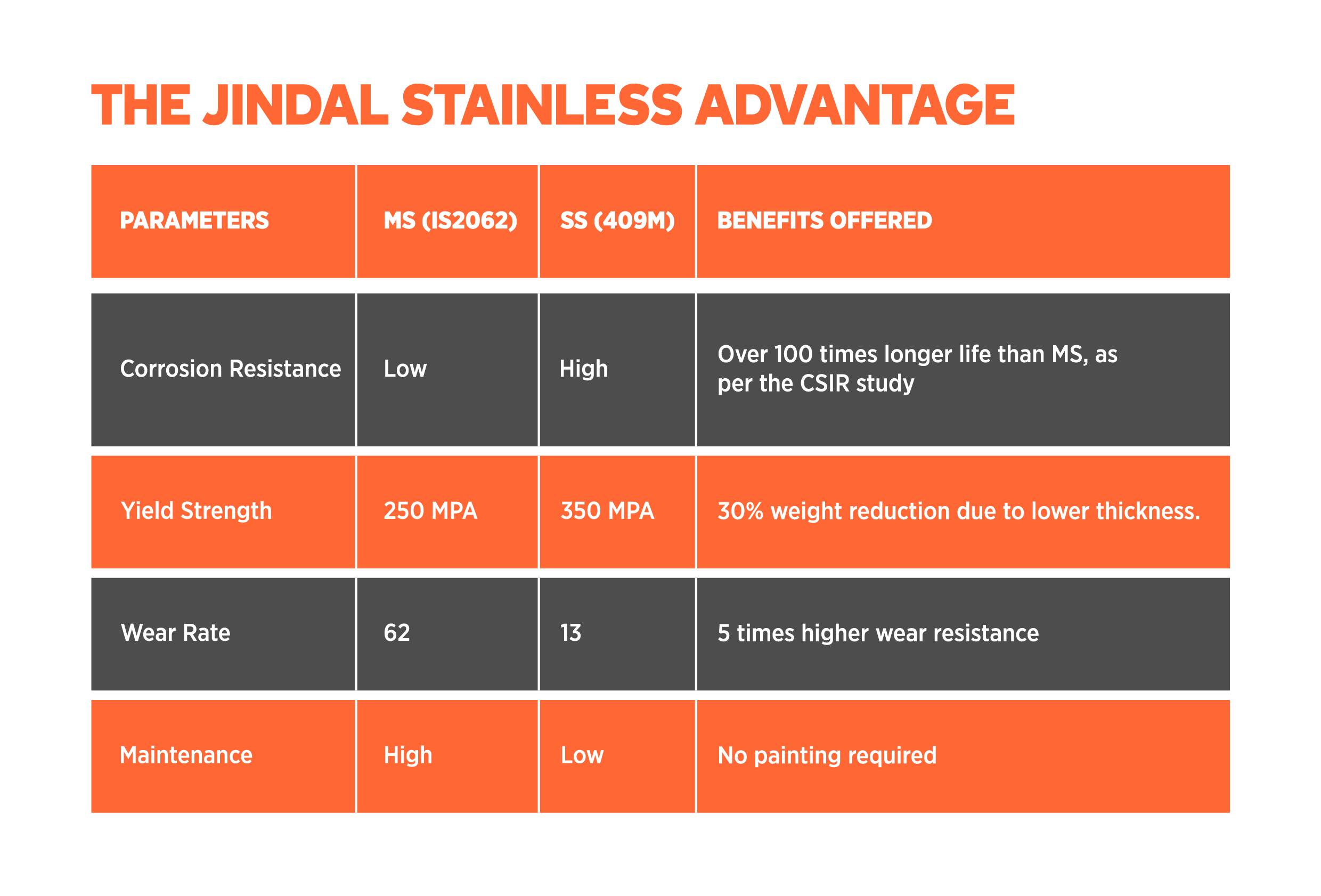

Advantages of using 409M Stainless Steel instead of Mild Steel for the Upper Deck Plate of Crude Oil Tanks

Corrosion Resistance:

Stainless steel 409M is highly resistant to corrosion, making it ideal for environments exposed to saline air and rainwater retention. Mild steel, on the other hand, is prone to corrosion over time, which can weaken roof plates and lead to leaks or other issues.

Durability:

Stainless steel is a very durable material, capable of withstanding high levels of stress and pressure without deforming or cracking. This is crucial for roof plates in crude oil tanks, as they must support the weight of the oil and any additional equipment installed on the roof.

Low Maintenance:

Unlike mild steel, which requires regular painting and coating to prevent corrosion, stainless steel 409M eliminates these needs. Its low maintenance significantly reduces operational costs over the tank's lifecycle.

Project Highlights

Application: Upper Deck Plate for a 60,000 KL Crude Oil Tank

Segment: Oil and Gas

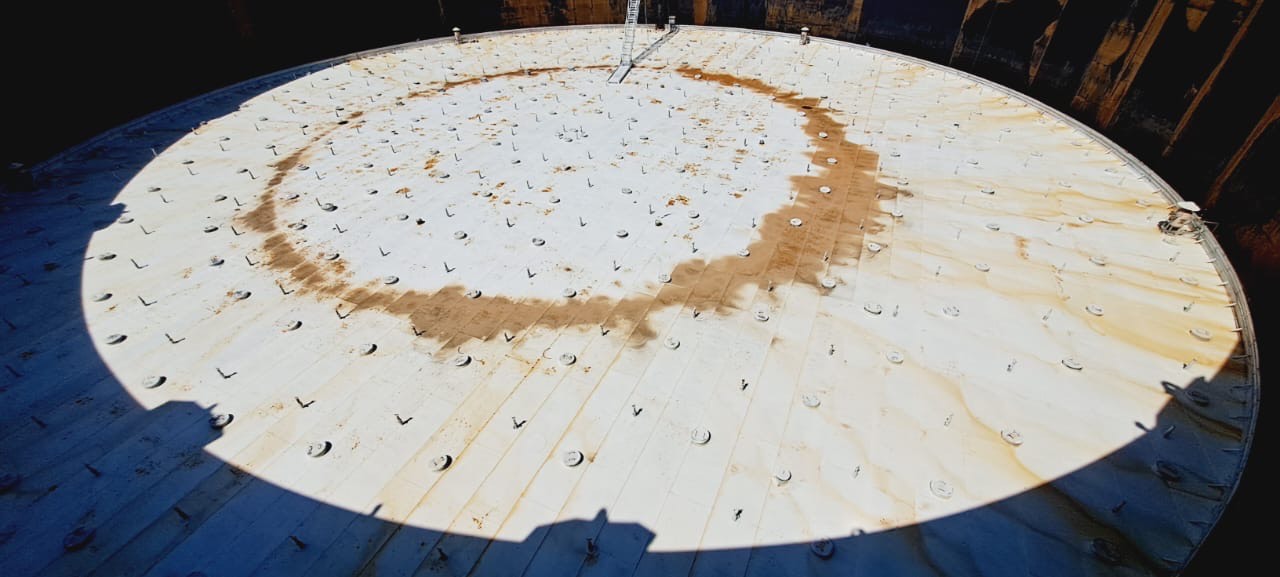

The project involved replacing traditional mild steel (MS) plates, which were painted with high-quality coatings but still faced challenges such as corrosion, frequent maintenance, and repainting (as seen in the images above). These challenges not only increased costs but also posed risks to the structural integrity of the tank.

In 2021, Jindal Stainless Limited implemented an innovative solution by installing 10 MT of 409M grade stainless steel plates (pilot) without the need for any painting. The stainless steel plates, shown in the images, provide:

- Superior Corrosion Resistance: Unlike MS plates that showed visible corrosion and degradation, the 409M stainless steel plates have remained intact and resistant to environmental factors such as rainwater retention and saline air.

- Long-Term Durability: The stainless steel upper deck plates have proven to withstand the harsh conditions of crude oil tank environments without significant wear or need for additional coatings.

- Reduced Maintenance and Costs: By eliminating the need for regular painting and maintenance, the project has significantly reduced lifecycle costs for the crude oil tank.

- Sustainability: The use of unpainted 409M stainless steel has minimized the environmental impact by reducing CO2 emissions associated with maintenance and repainting.

The successful use of 409M stainless steel in this project has set a benchmark for future applications in the oil and gas industry, demonstrating the material's exceptional performance and long-term benefits.

The Bigger Picture – Industrial Projects for Crude Oil Applications and Stainless Steel

Industrial projects for crude oil applications require durable and corrosion-resistant materials to ensure the safety and longevity of the tanks. The use of stainless steel upper deck plates over mild steel plates is an important step towards achieving this goal, as is evident in the case study.

Jindal Stainless is committed to providing high-quality stainless steel to support India's growing infrastructure requirements. The replacement of mild steel roof plates of India’s leading oil processing company with stainless steel roof plates in crude oil tanks is a prime example of Jindal Stainless's commitment to sustainability, safety, and innovation.

This case study is likely to become a precedent for future applications, as more industries realize the benefits of stainless steel in their projects. With its high-quality products, technical expertise, and commitment to sustainable development, Jindal Stainless is poised to play a leading role in India's journey towards becoming a more modern, efficient, and sustainable economy.

Don’t settle for outdated solutions in crude oil tank roof applications. Discover how Jindal Stainless Limited’s 409M stainless steel is transforming refinery projects with unmatched durability, corrosion resistance, and sustainability.

Learn more about how 409M stainless steel can elevate your refinery projects.

Reach out to us at salesdevprocess@jindalstainless.com, dhirendra.singh@jindalstainless.com