Monthly

Stainless Trivia

Fill in your answer below

Introduction

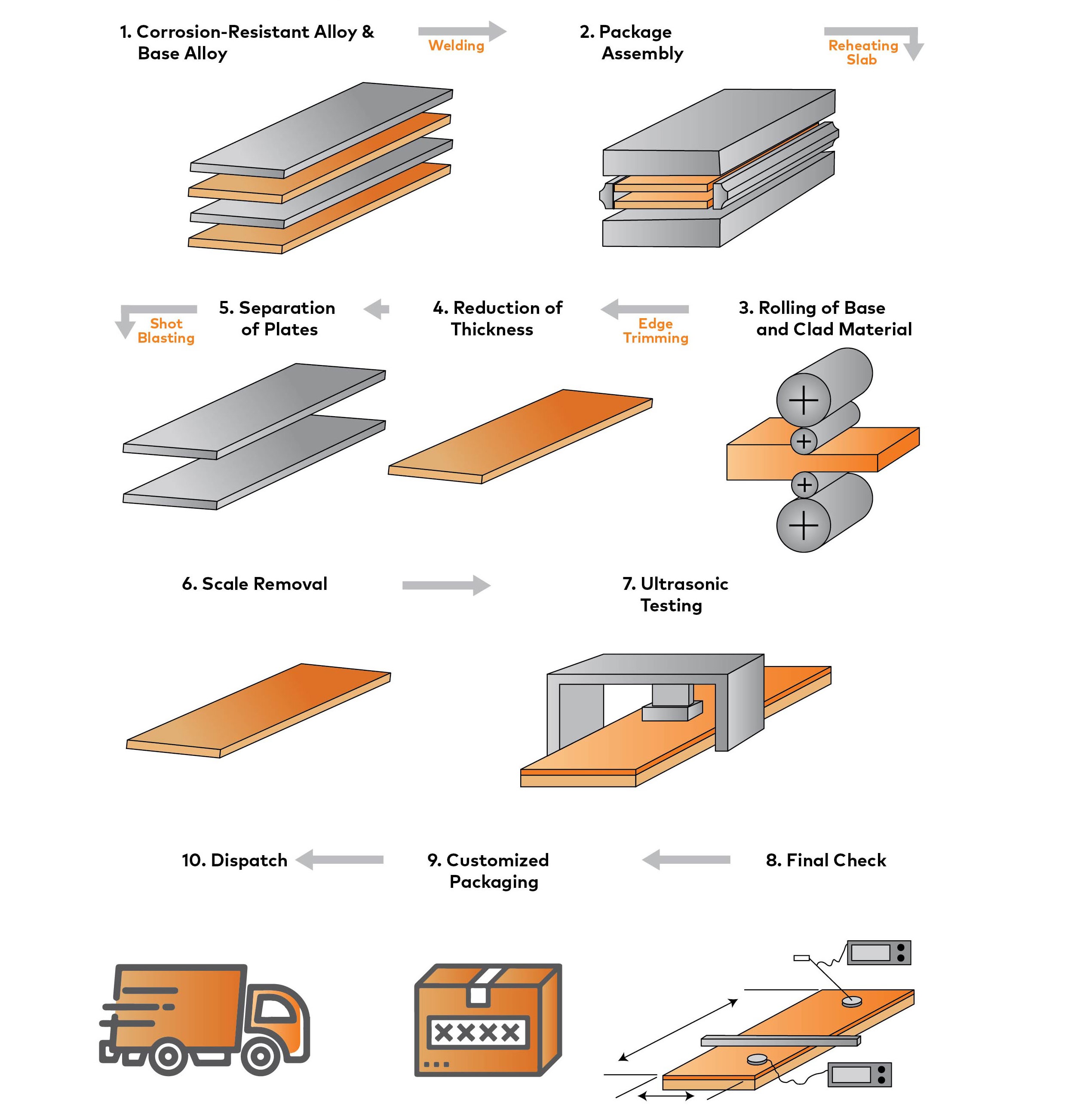

Jindal Stainless has achieved a remarkable milestone with the successful indigenous development of Hot Roll Bonded Clad Plates through our dedicated in-house R&D, a crucial material now utilized in power generation, oil & gas, and chemical processing industries. This breakthrough not only reinforces our position as a leader in advanced material manufacturing but also aligns with the ‘Atmanirbhar Bharat’ initiative by significantly reducing dependency on imports.

A pivotal driver behind this achievement has been our strategic collaboration with Bharat Heavy Electricals Limited (BHEL), India’s foremost maharatna power sector company. Through this partnership, we have successfully fulfilled BHEL’s demanding requirements for Flue Gas Desulfurization (FGD) systems in thermal power plants. In addition to the BHEL order, we have also completed 2-3 other significant orders, further demonstrating the quality and reliability of our domestically produced clad plates. This progress has led to faster project execution, cost savings, and reduced lead times for critical infrastructure projects, advancing national self-reliance and ensuring India’s key sectors have access to world-class materials without the need for imports.

Challenge

Historically, India relied on imports for clad plates, particularly Nickel Alloy Cladded Plates like C276 ( highly valued for its exceptional corrosion resistance), which are widely used in Flue Gas Desulphurization (FGD) systems in thermal power plants. The absence of indigenous production resulted in extended project timelines and significant foreign exchange outflows. Recognizing the growing demand for these high-performance materials, Jindal Stainless embarked on a mission to develop the capability to produce Hot Roll Bonded Clad Plates domestically.

Technical Excellence

Materials and Composition

The C276 Nickel Alloy, used for cladding, provides exceptional corrosion resistance in aggressive environments, while the carbon steel base imparts structural strength. The hot roll bonding process ensures uniform bonding between these two materials, enabling the plates to perform effectively in the most demanding industrial applications.

Quality Assurance and Testing

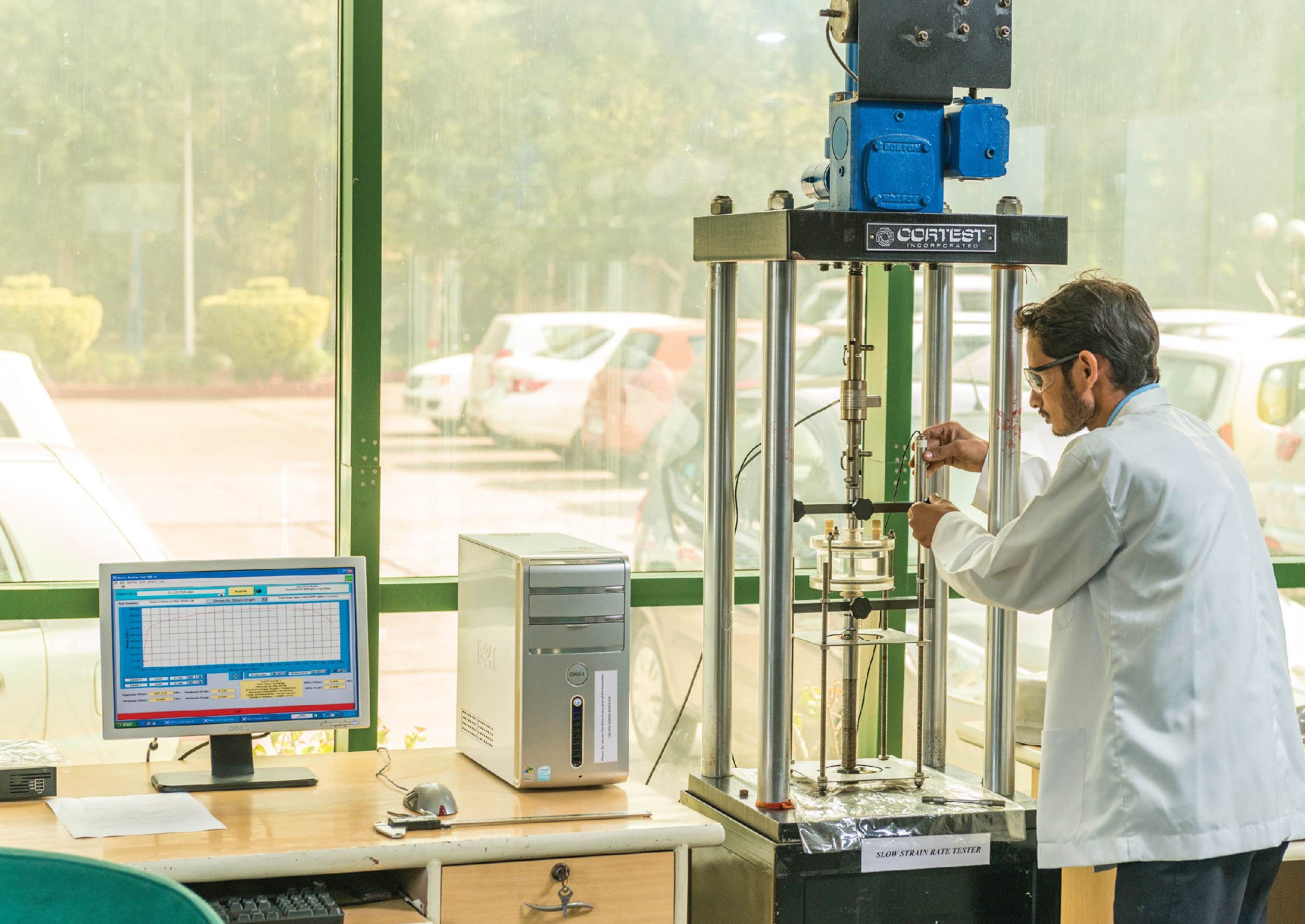

Jindal Stainless ensures that all Hot Roll Bonded Clad Plates meet stringent global standards such as ASTM A264 and A265 which define the quality of bonding and material performance. Key testing protocols include:

- Tensile and Bend Tests to assess mechanical properties and bond quality.

- Shear Strength Test to ensure minimum bond strength.

- Shear Strength Test to ensure minimum bond strength.

The primary application for these plates is in FGD systems of thermal power plants, which are critical for reducing sulfur dioxide emissions and meeting environmental standards set by the Ministry of Environment, Forest and Climate Change (MoEFCC).These rigorous tests ensure that the plates not only meet but exceed performance expectations, especially in sectors like power and chemical processing where failure is not an option.

Beyond our pioneering C276 Nickel Alloy Clad Plates, Jindal Stainless offers an extensive range of clad materials tailored to diverse industrial needs. From versatile Stainless Steel to high-performance Nickel Alloy Clad Plates, our comprehensive portfolio delivers optimal solutions for complex applications. For a detailed overview of all our offerings, please refer to the end of this blog.