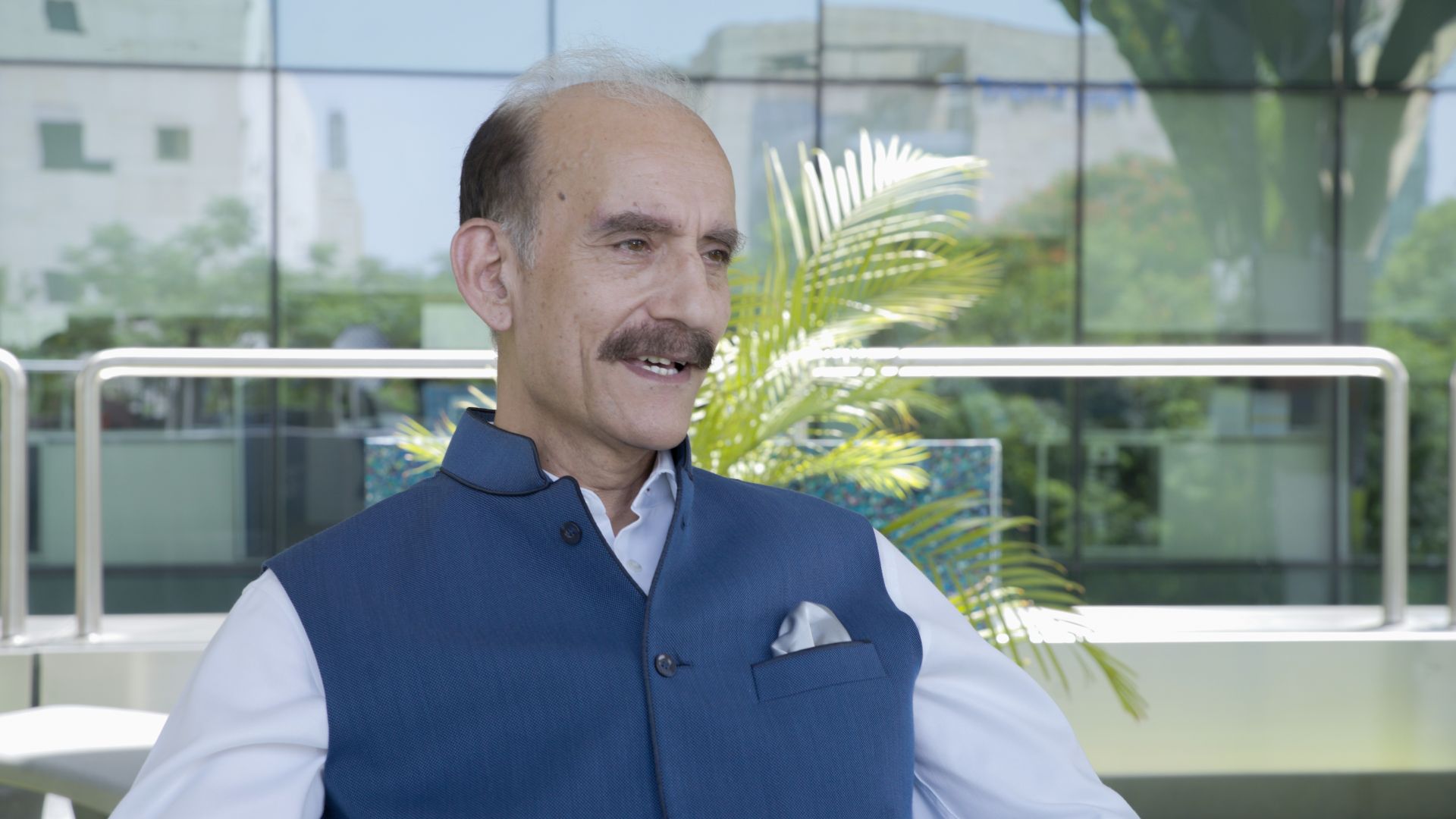

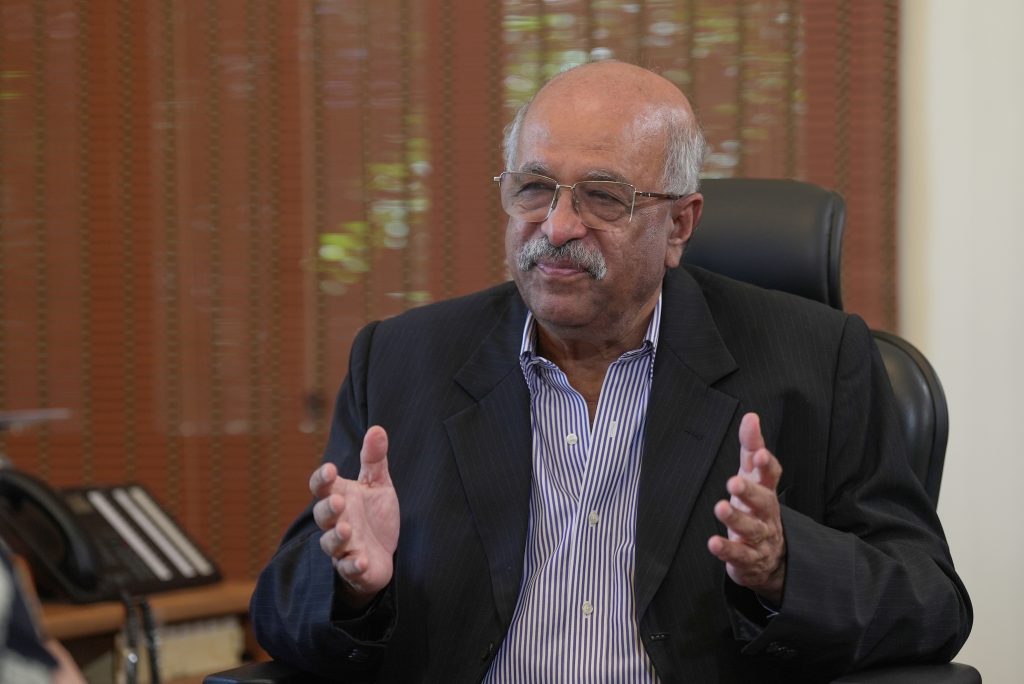

Interview of Joint Managing Director, Johnson Lifts, Mr VM Thomas

September 27, 2024

In this edition, we had the pleasure of sitting down with the Joint Managing Director of Johnson Lifts and Escalators, Mr VM Thomas, a leader whose humility and courteous nature immediately stood out. Our conversation spanned the evolution of India’s lift and escalator industry, as well as the incredible journey he has led in building a successful enterprise that was started by Mr K J John. From the Prime Minister’s Office in Delhi to majority of metro stations across the country to the Ram Mandir, Johnson Lifts and Escalators has supplied lifts for some of India’s most prestigious projects. As the first Indian company to start manufacturing escalators domestically, this swadeshi brand has played a critical role in the industry.

Standing tall and always with a smile, Mr Thomas embodies a leadership style grounded in passion and hard work. His insights are both inspiring and motivating, offering valuable lessons for aspiring leaders in the industry. Read about this interesting conversation between Supriya Sundriyal from Corporate Communications and Mr VM Thomas.

Can you please tell us something about yourself?

I’m a mechanical engineer by profession. I graduated from IIT Madras in 1973. Subsequently, I joined Hindustan Aeronautics as a management trainee and in 1985, I moved over to Johnson lifts. And it’s an association of almost 40 years. Yeah, it’s been a long one.

What about Johnson Lifts? If you can tell us more about the company.

It’s a 100% Indian company and a private limited company. Started in 1963 by Late Mr K.J. John. Initially it was a maintenance company. And subsequently, in 1970, he started manufacturing lifts. Right now, we operate pan India and we have about 82 branches. We have four factories spread across the country. With manufacturing area of almost 1 million or 10,00,000 sq. ft., we are over 8000 employees. We also export our product to many of our neighbouring countries, Middle East, Saudi Arabia, and the African countries.

Sir, what are your key projects and target markets?

Target markets are basically, housing, apartment buildings. Then, of course, commercial buildings, then railways quite a bit of openings are there. And metros, airports. And of course, as I said exports.

Any prestigious projects that you’ve been a part of?

Of course there are many in fact. I am very proud to say that we are the ones who supplied all the lifts in the New Parliament building, which was very prestigious. We are currently supplying and erecting the PMO’s office and then we supplied the lifts and escalators in Varanasi railway station and Ram Mandir. Right now, we are erecting escalator in Leh airport, which is one of the highest altitude wise. Then we erected lifts in Pamban Bridge.

Recently, the temple in the UAE. It was a very special project because the pujaris had certain specifications that the lift should not touch the earth, so we had to do some special fixtures for that. And many more.

Sir, yours is one of the oldest Swadeshi companies to have started manufacturing escalators and lifts. How have you seen the evolution of the industry in terms of national growth and globally?

Earlier, after the independence probably, we only had about 3 or 4 Indian companies and all of them do not exist now. Worth mentioning that today we have 2 or 3 Indian companies, which all started much later. We have been competing with all multi-nationals, like OTIS, KONE, SCHINDLER, Mitsubishi, Toshiba, Fujitec, you name it. All the multi-nationals are in India. So obviously our product has to be up to their standards in quality and service as well as the safety standards. And we have been matching them in every sense. If you look at the evolution of lifts of what it was in the 50s and what it is today, there are tremendous changes. First of all, when I talk about the drive mechanism, elevator motor is coupled on the gear. And then you have the output. This slowly changed over to two speed motors. Then to the DC motors. The whole idea behind this was for smooth acceleration and deceleration of travel. Then we see the VVVF drives introduced in driving the motor. Now it is the permanent magnetic motors, which usually gives good acceleration and deceleration. And this ride is very smooth. In fact, we were the first to introduce the VVVF drive in India. I mean, that is not a small joke. And similarly, if you see the controller, those days, the controller was more or less, let’s say 80% mechanical and only maybe 15 or 20% electrical. Today the design have changed completely. First to microprocessor based controllers and then microprocessor with VVVF drives and serial communication. So there is a tremendous change, evolution of what was in the 50s and the 60s and what it is today. Even the manufacturing processes and materials there are big changes. And it is the same all over the world. So that’s why we have come a long way. And we have matched the best products in the world.

How has the growth in major urban infrastructure development programmes helped your industry?

It was basically housing. It was a big boom in the 70s and the 80s and in housing and then a lot of multi-storied buildings came up along with that. The office buildings came up and the infrastructure was started in the early 2000 and they took some time to catch up in the railways. And then the metros and airports. And so all these projects are prestigious.

And what are your upcoming projects? If you can mention some of them.

We have almost done 20 metros in India. And right now we are doing about ten metros. For example, the Delhi fourth stage, Bangalore second stage, and Chennai second stage, Nagpur metro, Pune metro, Kolkata metro. The metros are big job that provide us enough work for lift as well as for escalators. Escalators have to be manufactured as per their standards.

And then, housing is booming and I think it’s doing very well. Similarly office complex, office buildings requirements have gone up. The malls have gone up. Railways have been into big projects like they’re trying to renovate or they’re going to change almost all the big railway stations, even the small railway stations – traveller friendly railway stations requiring escalators and elevators. A small station, require minimum 4 escalators and 2 or 3 elevators. The things are changing.

I’m sure there’s a lot of competition also in the market. So what kind of R&D are you bringing in to face this competition?

As I told you, we have to match the multi-nationals in every sense, be in quality, innovations, or in service. We have to match the multi-nationals. And we understand that and we are fully geared up for that. We have an Innovation Centre here, where about 50 engineers seriously work in it. And we have a test tower of 150ft, where we test all the components. And then only we put them in the regular production. We are also putting up a test tower, one of 300ft, which would be the highest in India. When we put up the 150 ft one, we were the highest. We understand that over a period of time, things are going to change. The new concepts are going to come up. We are funding few start-ups, not in India but abroad. Let’s hope that some crazy ideas will come up. And then the entirely new concept is in vertical transportation.

Talking about the input material now, how do you think stainless steel fits into manufacturing lifts and escalators? What do you think about this input material?

Earlier, it was all wood. The cabin used to be wood. And then subsequently, it changed to steel etc. Stainless Steel was accepted very well in the market, both by the customer as well as by the manufacturer. The customer liked it because of its surface, quality, durability, new look, and of course, designer stainless steel sheets. It also gives you a really a nice feeling. And the manufacturer like it because the existing machineries could handle both mild steel as well as stainless steel.

Sir, when did your collaboration with Jindal Stainless begin? And what do you think about this collaboration?

Earlier the stainless steel finish was plain and I think when Jindal came, things slowly changed. We have the association (with JSL) for the last 15 years and it has been very good and then many occasions, they have been coming up with meeting our requirements, especially some of the designer sheets you have developed is wonderful. I mean, earlier we had a problem, we used to import these sheets from UK. And we ran into some difficulties in importing these because of the excise duty, government policies. Jindal Stainless stepped in very well. And then solved our issues.

So you’ve been associated with Johnson for more than four decades now. What is that one message that you would like to give to the future leaders who wish to take their company to new heights?

I wish I had a one sentence answer for this. You’ve got to be very passionate about your company. There’s no two ways about it. If you ask me that, probably you go to sleep with that. And it has to be a 24×7 product and it has to be with you all the time. And you got to be with it all the time on the lookout for new ideas, new concept, what’s going on in the market? What the customer wants? Then I think it’s hard work. And I would say along with that, sincerity. You got to be sincere. You got to be sincere with your suppliers, and you got to be sincere with your colleagues and subordinates. I think that has been my principle. I would bet if a guy is really passionate about what he does, I’m sure that he’s bound to succeed.