Introduction

Decorative pipes and tubes play a pivotal role in enhancing the aesthetic appeal of various spaces, combining functionality with artistic design. Beyond their utilitarian purpose, these specialised stainless steel components are crafted to elevate interior and exterior environments, offering a seamless blend of form and function. The decorative pipes and tubes industry has witnessed a transformative shift, driven by advancements in manufacturing technologies and a growing demand for innovative design solutions. As architects and designers increasingly prioritise aesthetics alongside functionality, decorative stainless steel components have become integral to modern construction and design practices.

Applications of decorative pipes and tubes

Stainless steel Pipes are used in a wide range of applications ranging from handrails and balustrades in buildings, staircases and balconies to crafting frames for furniture such as chairs, tables and beds. They are also utilised in fabrication of gates, decorative fencing and outdoor structures such as pergolas and in architectural signage in commercial buildings and public spaces. The inherent strength and durability of stainless steel makes it an ideal material for diverse applications, ensuring not only a secure structure but also a long-lasting one that retains its aesthetic appeal over time.

Stainless steel provides architects and designers with a material that not only meets structural and safety requirements but also lends itself beautifully to diverse design visions. Whether used in sleek, modern gates or intricately designed classical entrances, stainless steel's adaptability aligns with the evolving landscape of architectural creativity, offering both form and function.

As technology advances, stainless steel pipes and tubes continue to find new applications, from innovative designs in interior décor to the intricate piping systems of cutting-edge manufacturing processes. The adaptability and reliability of stainless steel make it an enduring choice, contributing to the functionality, safety and aesthetic appeal of diverse applications across various industries.As technological advancements continue to unfold, stainless steel pipes and tubes continue to find new applications, from innovative designs in interior décor to the intricate piping systems of cutting-edge manufacturing processes. The adaptability and reliability of stainless steel make it an enduring choice, contributing to the functionality, safety, and aesthetic appeal of diverse applications across various industries.

Challenges faced by P&T segment

For a long time, JSL faced a significant problem with its decorative pipes and tubes (P&T) in India. About 25% of these stainless steel products, which had the JSL brand name on them, turned out to be fake. These imitation products were sold at prices that were 10-15% lower than real JSL products. This caused a lot of issues for JSL. These fake products not only hurt the company's sales, they also made JSL lose its position in the market for decorative stainless steel pipes and tubes. The problem went beyond merely financial repercussions – it affected how much people trusted the JSL brand. People who bought the cheaper fake products ended up with poorer quality items, and this damaged their opinion of JSL, hurting the company's reputation. Additionally, JSL had to deal with legal problems related to intellectual property rights, trademarks and following the rules.

Forging brilliance amidst adversity: JSL's trailblazing solutions to overcome challenges in the P&T segment

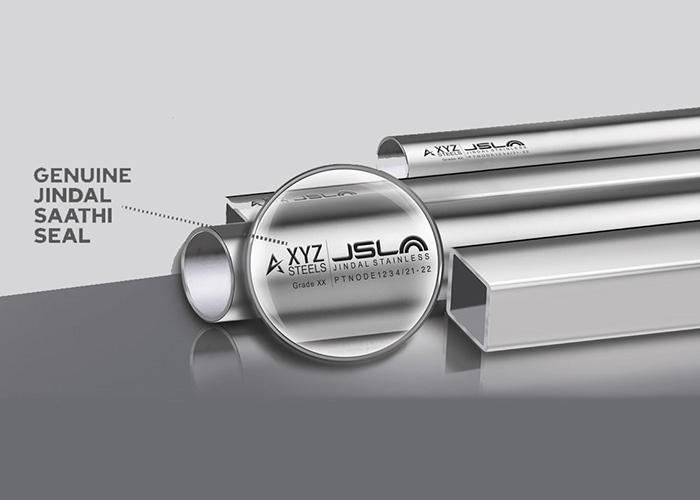

To counter these challenges, JSL decided to take a big step. They started a new initiative to co-brand their stainless steel products to clearly demarcate the products that are real and those that are fake. The goal was not just to stop fake products but also to win back the customers they lost, rebuild their market position and make people trust the JSL brand again. The co-branding scheme implemented by JSL stands as a strategic response to market infringement by sub-standard products, establishing a significant point of differentiation from competitors. The scheme ensures the delivery of high-quality material to consumers, fostering trust and creating greater value for customers. Jindal Stainless Limited (JSL) and Jindal Stainless Steelway Ltd. (JSSL) took the initiative of onboarding 142 pipe and tube manufacturers as Memorandum of Understanding (MoU) partners and empowered these partners to utilise a standard seal on their decorative pipes and tubes.

For co-branding, JSL developed a distinctive seal encompassing the brand logos of both Jindal Stainless and its respective partners, with a unique MoU number assigned to each partner, adding details regarding the grade of stainless steel used. The comprehensive approach not only expanded brand awareness for stainless steel Pipe & Tube manufacturers but also addressed challenges associated with counterfeiting.

To catalyse the adoption of the co-branding initiative, JSL launched an extensive promotional campaign aimed at raising awareness and enticing participation from industry giants. Initial attempts to use laser technology for logo printing faced setbacks during the polishing process, prompting a strategic pivot. Undeterred, JSL opted for the reliability of conventional logo embossing practices, aligning seamlessly with the established norms in the stainless steel pipe and tube industry. This adaptive approach not only showcased JSL's commitment to innovation but also underscored the resilience required to navigate the intricacies of a competitive market landscape.

Outcome

This proactive measure yielded promising results, successfully reducing the counterfeit rate post-implementation. The implications of this reduction are far-reaching; customer perception has seen a marked improvement with enhanced trust and a positive shift in perceptions of product quality. Partners also benefitted from a reduction in problems like low market share, lower margins, reputational loss and the intrusion of inferior-quality stainless steel into the market.

Jindal Stainless Limited or JSL's market share is poised for growth, with an expected increase of 7% after the completion of phase 1 of the co-branding initiative. Notably, the company has already surpassed its market share target of 60% for the fiscal year 2020-21 compared to its previous market share of 44-50%. This success underscores the effectiveness of the co-branding strategy in not only mitigating counterfeit challenges but also fortifying JSL's market position and reputation.

The Saathi Seal also emerged as an equaliser, empowering smaller entrants in the pipe and tube (P&T) segment to compete on a more balanced platform. Earlier, the market leaders in P&T segment held sway, dominating both in brand recognition and market share in the highly competitive realm of the P&T market, which presented a formidable challenge for smaller and newer players.

Know More