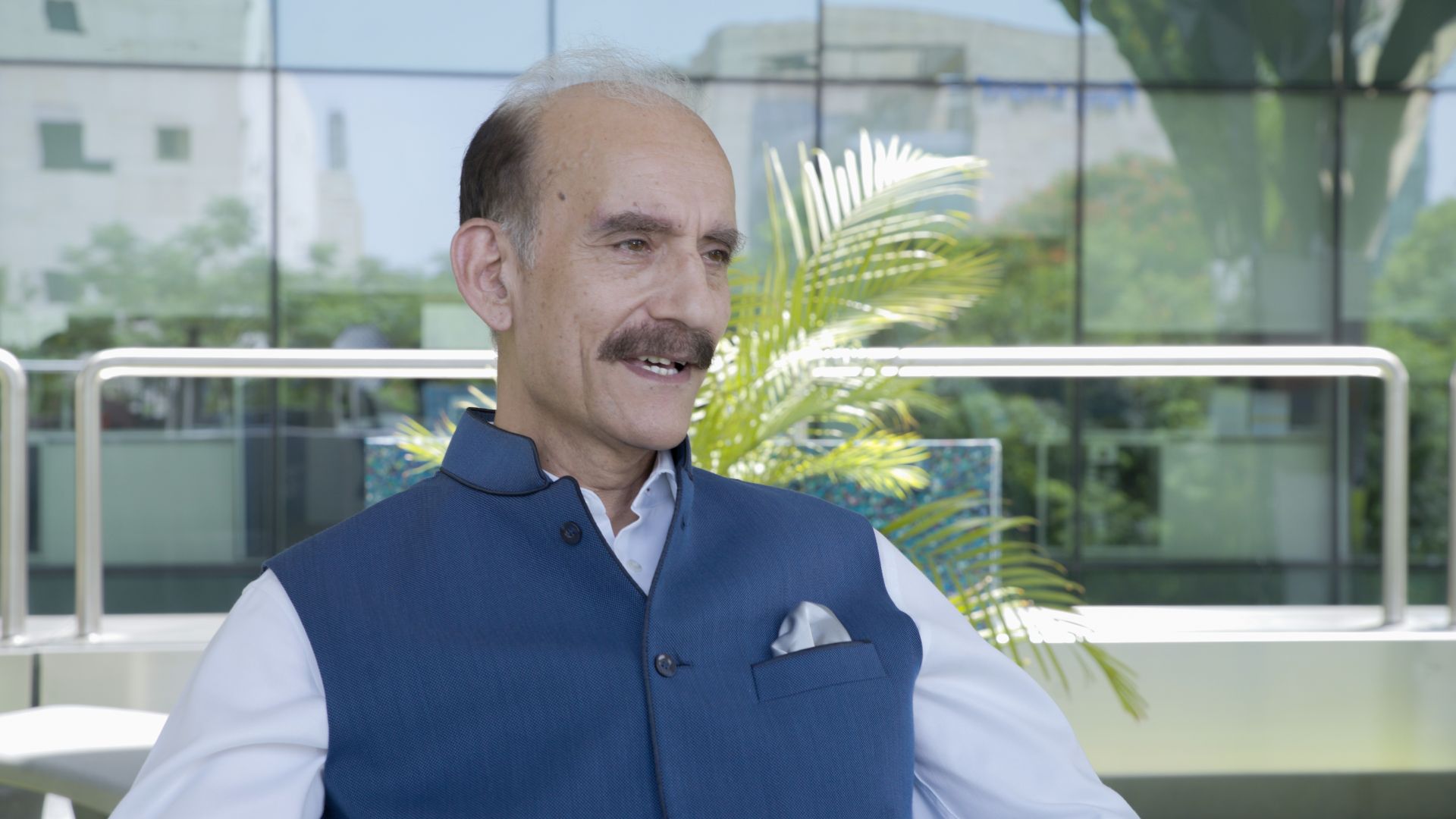

Mr Florent Stroebel

July 25, 2023

“The next generation of engineers holds the key to shaping our future and solving the challenges ahead”, says ED, Cryolor Asia Pacific Private Limited, Mr Florent Stroebel. A Mathematics-teacher-turned engineer, Mr Stroebel strongly feels that the future engineers should indulge in sustainable practices. Read this interview about a French national, who has been in the metals industry for more than two decades now, and has observed the industry evolve over years.

Tell us about yourself (childhood, education, profession, aspirations, hobbies, etc. – mix of personal and professional profiling)

My name is Florent Stroebel and I am a French national. I was born in 1976 in Paris. I did Industrial engineering from ICAM College in France. Engineering was an easy choice as I always wanted to do something that would contribute in making others’ lives easier and comfortable.

After completing my studies, I immediately started working. At the onset, I was a Mathematics teacher in Toussiana Private School in Burkina Faso, a country in Africa. It was an exceptional experience for me as I stayed there for two years and taught grades 7 to 9. Post that, I entered the metals industry and have continued to be a part of it for more than 20 years now. I was an Erection Supervisor at Fives ECL, a leading company in aluminium smelter technology. After my short stint at ECL, I moved to ASCOMETAL as an Engineering Department Manager. ASCOMETAL manufactures and delivers long engineering products for various industries.

Currently, I am the General Manager of Cryolor Asia Pacific. Cryolor is a 40-year-old company that specializes in designing and manufacturing cryogenic equipment for transport and storage of liquefied gases. We have been serving all geographies, exporting to more than 80 countries, with 500+ customers worldwide. We will continue providing our best quality products with state of art manufacturing facility located in Chennai.

Since you have been in the industry for more than twenty years now, how do you think the usage of stainless steel has diversified? Also, why stainless steel?

While I may not have been directly involved in the stainless steel industry, I have observed its evolution from a distance. Over the years, I have witnessed the remarkable diversification of stainless steel usage. Initially limited to cookware, it has now found its way into various flourishing industries, including processing, architecture, railways, and of course cryogenic industry, both in India and internationally. Stainless steel has undoubtedly claimed a significant and expanding role across these sectors.

The exceptional resistance to corrosion and ability to withstand extreme low temperatures are the key characteristics to manufacture our Cryogenic tanks. It allows us to fulfil the stringent ASME and PED code requirements for pressure vessels. These advantages have definitely contributed to the world wide recognised quality of our products. We are confident that we will both grow in the coming years with JSL

Since carbon footprint is a major issue, how are you working to reduce it?

Absolutely, we acknowledge the importance of reducing our carbon footprint, and we have taken proactive measures to work towards this goal. One of our primary focuses is optimizing power and water consumption within our operations. Recognizing that approximately 70% of electricity supply in India is derived from coal, we are committed to reducing our electric consumption to contribute to a greener future.

Our dedicated team is actively engaged in the energy transition, exploring sustainable alternatives like solar panels, and implementing eco-friendly practices throughout our processes. Beyond just internal efforts, we are also committed to assisting our customers and suppliers in their journey towards reducing carbon emissions. Our goal is to foster a collective impact on the environment, not only within our organization but also in partnership with those we serve.

When and how did your association with Jindal Stainless begin?

We started working with Jindal Stainless in 2011. Before that, we used to source stainless steel from suppliers outside of India. However, when we found out that Jindal Stainless was producing good quality stainless steel solutions, we started procuring the material from them. Apart from their quality, it is important to mention about their on-time delivery services. Their punctuality has been impressive and adds further value to our partnership.

Any message that you would like to give to the upcoming engineers?

The next generation of engineers holds the key to shaping our future and solving the challenges ahead. We are fortunate to be living in an era with advanced technologies that can aid in these endeavors. I firmly believe that Gen Z, as they are often referred to, exhibits a heightened awareness of their surroundings. They show a deep concern for the environment and are determined to pursue roles that make a positive impact. Therefore, my only message to them would be to indulge in sustainable practices and care for the nature.