Food Processing

Stainless steel is the perfect material for food processing as it provides excellent corrosion resistance and chemical inertness. It can handle rigorous demands of preparing, processing and storing beverages, dairy, and food products. With its easy cleaning and sterilization properties, stainless steel ensures hygiene and maintains its integrity during fabrication. Various types of stainless steel, such as austenitic, ferritic, martensitic, and duplex, are employed in beverage, dairy, and food applications based on their specific corrosion resistance and operational needs.

Key Advantages of

Stainless Steel in Food Processing Industry

Corrosion resisant

Easy to clean

Chemically inert

Longer life

Low life cycle cost

~100% Recyclable

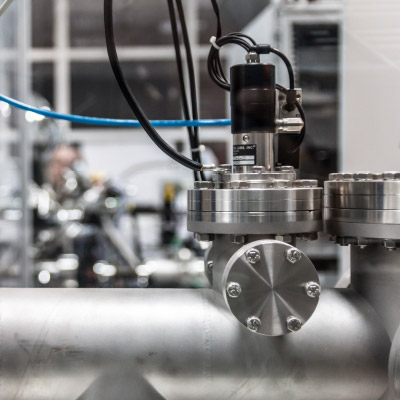

Applications of Stainless Steel in Food Processing Industry

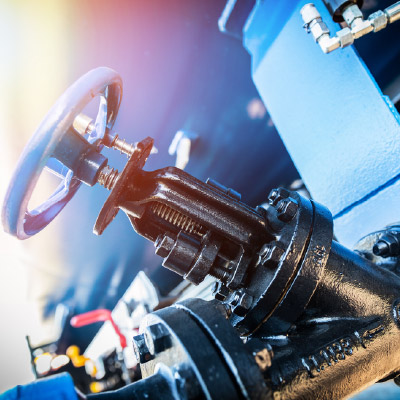

Chemical Industry

Stainless steel pipes and tubes are essential in the chemical, processing, and oil & gas industries, offering superior corrosion resistance, high-temperature resistance, and low temperature resistance. They provide a solid foundation to withstand the rigorous process and environment conditions in petrochemical, fertilizers various chemical manufacturing industries including both organic and inorganic chemicals and acids.

These sectors drive the demand for specialized stainless steel in various process equipments like tanks, reactors, vessels, pipes, pumps, and valves. These grades exhibit exceptional corrosion resistance and superior mechanical properties across different process conditions, making them ideal for critical applications in handing critical process and applications in chemical and petrochemical and other industry-specific needs.

Key Advantages of

Stainless Steel in Chemical Industry

Corrosion resistant

Abrasion resistant

Easy fabrication

Superior Hygiene

Chemically inert

Efficient heat transfer

Low life cycle cost

Low-maintenance